6-54

2007 Buell Ulysses: Drive/Transmission

HOME

INSTALLATION

1.

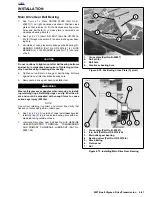

See

Figure 6-101.

Install transmission sprocket (4) with

secondary drive belt onto main drive gear (5).

2.

Place transmission in neutral.

3.

Apply a few drops of LOCTITE 271 (red) to the left-hand

threads of transmission sprocket nut (3) and lightly coat

the washer-faced side with clean H-D 20W50 engine oil.

Wipe off any excess oil.

4.

Position nut with washer-faced side facing transmission

sprocket. Turn the nut counterclockwise to install it onto

main drive gear.

NOTE

Use the P3/Blast SPROCKET HOLDING TOOL (Part No. B-

43982) with the spacer and fastener from the 2003 Firebolt

SPROCKET LOCKING TOOL (B-45659) to hold the sprocket.

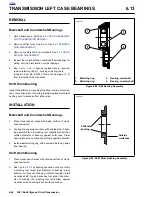

5.

See

Figure 6-103.

Install SPROCKET HOLDING TOOL

(Part No. B-43982) as shown.

6.

Using MAINSHAFT LOCKNUT WRENCH (Part No. HD-

94660-37B or H-D-46288) and a torque wrench, apply

LOCTITE 271 (red) and tighten sprocket nut to 50 ft-lbs

(67.8 Nm) INITIAL TORQUE ONLY.

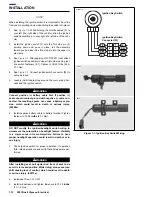

7.

See

Figure 6-104.

Scribe a line on the transmission

sprocket nut and continue the line on the transmission

sprocket as shown.

8.

Tighten the transmission sprocket nut an additional 30°-

40°.

NOTE

Maximum allowable tightening of sprocket nut is 45° of coun-

terclockwise rotation, after initially tightening to 50 ft-lbs. Do

not loosen sprocket nut while attempting to align the screw

holes. The lockplate has four screw holes and can be turned

to either side, so you should be able to find a position without

having to additionally tighten the nut. If you cannot align lock-

plate and sprocket screw holes, nut may be additionally tight-

ened to 45° as specified above. Tightening too much or too

little may cause the nut to come loose during vehicle opera-

tion.If you cannot align lockplate and sprocket screw holes,

nut may be additionally tightened until screw holes align.

NEVER LOOSEN nut to align the screw holes.

9.

See

Figure 6-101.

Install lockplate over nut so that two of

lockplate’s four drilled holes (diagonally opposite) align

with sprocket’s two tapped holes.

10. See

Figure 6-101.

Install two socket head screws

through aligned holes of lockplate and into tapped holes

of sprocket. Tighten to 90-110 in-lbs (10.2-12.4 Nm).

NOTE

See

Figure 6-101.

The original equipment socket head

screws (1) have thread-locking compound applied to them.

Since this compound remains effective for about three

removal/installation cycles, the original screws may be

reused up to three times. After the third removal/installation

cycle, replace both screws with new screws identical to the

original.

11. Install idler pulley. See

IDLER PULLEY INSTALLATION-

under

6.6 DRIVE BELT SYSTEM

.

Figure 6-103. Transmission Sprocket Tightening

Figure 6-104. Aligning Transmission Sprocket

1.

Sprocket holding tool

2.

Mainshaft locknut wrench

3.

Torque wrench

11979

2

1

3

45°

30°

a0163x6x

1.

Transmission sprocket nut

2.

Transmission sprocket

3.

Line scribed on nut and sprocket

3

2

1

Summary of Contents for 2007 ULYSSES

Page 17: ...A 16 2007 Buell Ulysses Appendix A HOME NOTES ...

Page 51: ...D 2 2007 Buell Ulysses Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115acsxu ...

Page 63: ...D 14 2007 Buell Ulysses Appendix D HOME NOTES ...

Page 73: ......

Page 103: ...1 30 2007 Buell Ulysses Maintenance HOME NOTES ...

Page 129: ......

Page 237: ...2 108 2007 Buell Ulysses Chassis HOME NOTES ...

Page 239: ......

Page 309: ...3 70 2007 Buell Ulysses Engine HOME NOTES ...

Page 347: ...3 108 2007 Buell Ulysses Engine HOME NOTES ...

Page 391: ...4 42 2007 Buell Ulysses Fuel System HOME NOTES ...

Page 481: ......

Page 505: ......

Page 561: ...6 56 2007 Buell Ulysses Drive Transmission HOME NOTES ...

Page 563: ......

Page 587: ...7 24 2007 Buell Ulysses Electrical HOME NOTES ...

Page 645: ...7 82 2007 Buell Ulysses Electrical HOME NOTES ...

Page 647: ......