App.

4-7

Confidential

Selector 4: Dual tone detection sensitivity in ICM recording

Setting this selector to "1" increases the tone detection sensitivity in ICM recording.

Selectors 5 and 6: Earth time length for earth function (Not used.)

These selectors set the short-circuiting time length of the telephone line (La or Lb) to ground.

This setting is effective only when the earth function is selected for the

R

key by using the

function switch.

Selectors 7 and 8: Break time length for flash function

These selectors set the break time length.

This setting is effective only when the flash function is selected for the

Search/Speed Dial

key by

using the function switch.

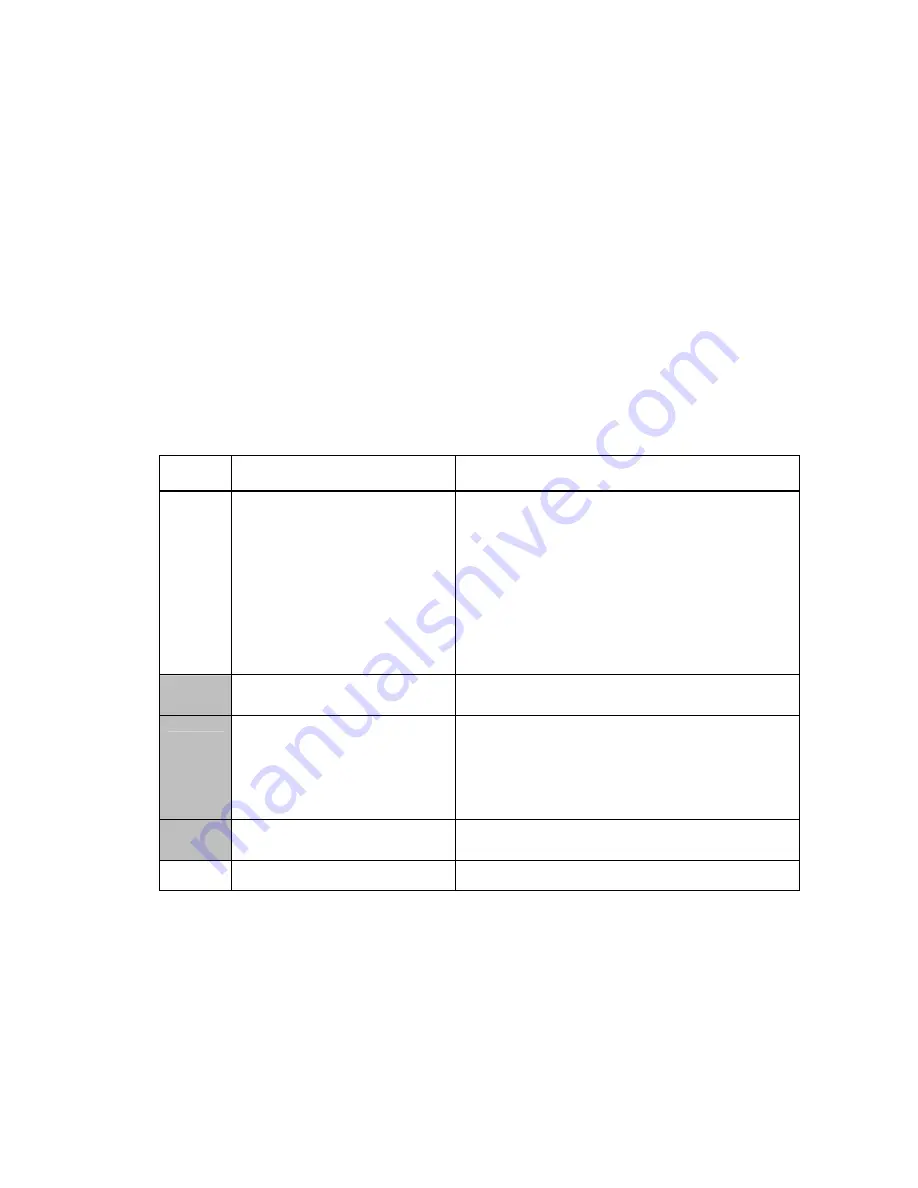

WSW05

(1st dial tone and busy tone detection)

Selector

No.

Function

Setting and Specifications

1

|

3

1st dial tone detection

No. 1 2 3

0 0 0

:

3.5 sec. WAIT

0 0 1

:

7.0 sec. WAIT

0 1 0

:

10.5 sec. WAIT

0 1 1

:

14.0 sec. WAIT

1 0 0

:

17.5 sec. WAIT

1 0 1

:

21.0 sec. WAIT

1 1 0

:

24.5 sec. WAIT

1 1 1

:

Detection (Without WAIT)

4

Max. pause time allowable for

remote ID code detection

0 : 2 seconds

1: 1 second

5

6

Busy tone detection in auto-

matic sending mode

No. 5 6

0

0

: No

detection

0 1 :

Detection only after dialing

1

0

: No

detection

1 1 :

Detection before and after dialing

7

Busy tone detection in auto-

matic receiving mode

0 : Yes

1: No

8 Not

used.

NOTE:

Selectors 5 through 7 are not applicable in those countries where no busy tone detection is

supported.

Summary of Contents for DCP-7010

Page 1: ...Confidential FACSIMILE EQUIPMENT SERVICE MANUAL MODELS MFC7420 7820N DCP7010 7020 7025 ...

Page 14: ...Confidential CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 20: ...Confidential CHAPTER 2 SPECIFICATIONS ...

Page 44: ...Confidential CHAPTER 3 THEORY OF OPERATION ...

Page 64: ......

Page 65: ...Confidential CHAPTER 4 TRANSFER OF DATA LEFT IN THE MACHINE TO BE SENT FOR REPAIR ...

Page 68: ...Confidential 4 2 Cover page sample End page sample ...

Page 69: ...Confidential CHAPTER 5 DISASSEMBLY REASSEMBLY AND LUBRICATION ...

Page 150: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...

Page 154: ...Confidential CHAPTER 7 CLEANING ...

Page 156: ...Confidential CHAPTER 8 MAINTENANCE MODE ...

Page 164: ...8 7 Confidential Scanning Compensation Data List a b c d e f g h i j k l m n q ...

Page 172: ...8 15 Confidential Configuration List ...

Page 178: ...8 21 Confidential Cover page sample End page sample ...

Page 187: ...Confidential CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING ...

Page 321: ...A NCU PCB MFC7420 U S A and CANADA models Confidential ...

Page 322: ...A NCU PCB MFC7820N U S A and CANADA models Confidential ...

Page 323: ...A NCU PCB MFC7420 EUROPE models Confidential ...

Page 324: ...A NCU PCB MFC7820N EUROPE models Confidential ...

Page 325: ...B Power Supply PCB 100V U S A and CANADA models Confidential ...

Page 326: ...B Power Supply PCB 200V EUROPE models Confidential ...

Page 327: ...December 04 SM FAX036 2 8C5A03 Printed in Japan ...