6

126305 Rev B 05/22/15

DANGER:

Circuit Breaker must be off prior to plugging anything into or unplugging anything

from the module.

DANGER:

When inserting the plugs into the connectors, make sure that the locking tab points

to the right side of the connector. Gently tug the wires to verify that the locking tab is

engaged. Failure to plug these in correctly will damage the module!

Communication:

The data for the module is also received through the J5 connector.

The module communicates directly to the POS via the strip in the

head of the unit and Interconnect Box (see figure 2.2

-

on previous

page).

NOTE:

•

The Pedestal must be mounted at least 18” from any dispenser or any area that’s classified

as Class 1 Division 1.

•

Installation must be in accordance with National Electric Code (NFPA 70), the Automotive

and Marine Service Code (NFPA 30A) and all State and Local Codes.

•

Use only Underwriters Listed Threaded Rigid Conduit and Listed Sealing Fitting with

conductor seals.

•

Field connections are done in the Upper Electrical Enclosure. Wire must extend 60 inches

above base of the unit to make Electrical Connections.

•

All conductors are to be stranded copper with THHN and gas and oil resistant insulation per

National Electrical Code.

•

Do not use wire smaller than 18 gauge.

•

These data wires should be twisted together at least 3 times per foot to reduce the effects of

electrical noise on the communication circuit. Due to the risk of noise causing possible

problems with communication, Bennett highly recommends the use of the twisted wires, but

does not require it.

•

Do not use wire nuts on Data Lines. Do not splice Data wires. They must be direct runs.

•

It is acceptable to pull the Data Lines in the same conduit as the terminal’s power.

•

Shims should only be used under Bolts to ensure the unit is level. Improper shimming that

results in misaligned frame is NOT covered under the Bennett Limited Warranty.

Field Wiring Diagram on Next Page

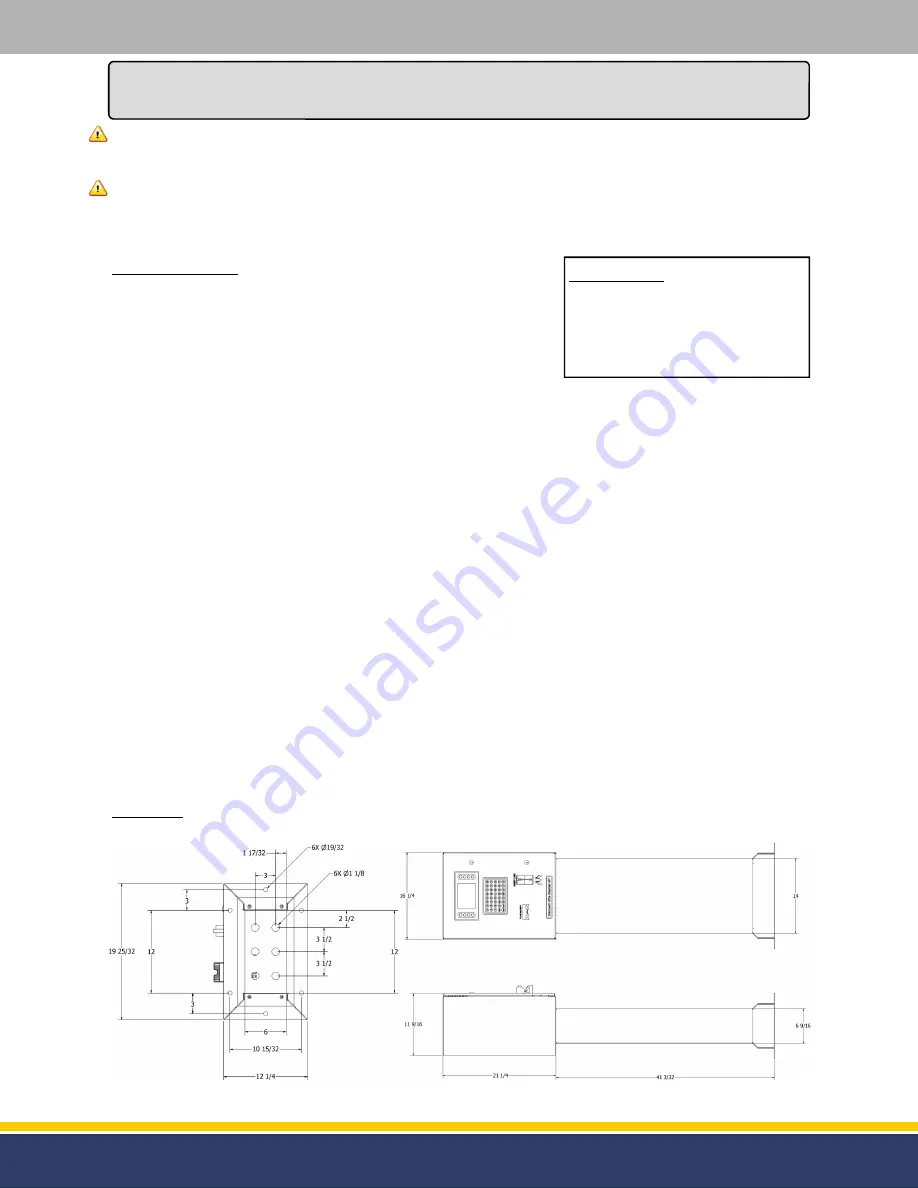

Footprint:

Installation

(continued...)

Field Wiring:

Data wires required for installation:

(1) 18 gauge for Data +

(1) 18 gauge for Common

(1) 18 gauge for Data

-