The CRI has been developed to provide maximum performance over land conditions.

Experience has shown that periodic maintenance of certain parts of the CRI is the best

way to help you avoid problems, so we suggest verification.

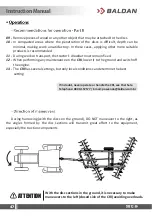

Lubrication is indispensable for the good performance and durability of CRI's moving

parts, contributing to the maintenance cost savings.

Before starting the operation, carefully lubricate all grease cups, always observing the

lubrication intervals in the following pages. Make sure of the lubricant quality regarding

its efficiency and purity, avoiding products contaminated by water, dust and other

agents.

Manufacturer

Types of grease recommended

Petrobrás

Lubrax GMA-2

Atlantic

Litholine MP 2

Ipiranga

Ipiflex 2

Castrol

LM 2

Mobil

Grease MP

Texaco

Marfak 2

Shell

Alvania EP 2

Esso

Multi H

Bardahl

Maxlub APG-2EP

Valvoline

Palladium MP-2

Petronas

Tutela Jota MP 2 EP

Tutela Alfa 2K

Tutela KP 2K

If there are equivalent manufacturers and/or brands that

are not listed in the table, consult the manufacturer's

technical manual.

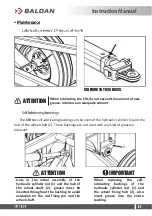

ATTENTION

Check nuts and bolts constantly, if necessary, retighten them.

General harrow retention maintenance should be done every

8 hours of work.

ATTENTION

Instruction Manual

Summary of Contents for CRI

Page 1: ...Drag Type Offset Disc Harrow Remote Control CRI 12 30...

Page 2: ......

Page 59: ...InstructionManual...

Page 62: ......

Page 64: ......

Page 67: ......