01 -

Before each job, check the condition of all hoses, pins, bolts, bearings, discs and

sections. Where necessary, retighten them.

02 -

The displacement speed should be carefully controlled according to the land´s

conditions.

03 -

The

CRI

is used in several applications, requiring knowledge and attention during

handling.

04 -

Only local conditions can determine the best method of operation of

CRI

.

05 -

When assembling or dismantling any part of the

CRI

, employ appropriate methods

and tools.

06 -

Carefully observe the lubrication intervals in the various lubrication points of the

CRI

. Respect the lubrication intervals.

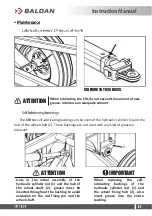

07 -

Always check if the parts have wears. If there is a need for replacement, always

demand Baldan original parts.

08 -

Keep the

CRI

discs always sharp.

Proper and periodic maintenance are necessary

to ensure the long life of CRI.

IMPORTANT

01 -

When storing the

CRI

, make a general cleaning and wash it thoroughly with water

only. Make sure the paint has not worn out, if it did, give a general coat, pass the

protective oil and fully lubricate the

CRI

. Do not use burned oil or other abrasive.

02 -

Fully lubricate the

CRI

. Check all moving parts of the

CRI

for wear and tear, make the

necessary adjustment or replacement of the parts, leaving the harrow ready for the

next job.

03 -

After all maintenance work, store the harrow in a covered and dry place, properly

supported.

Avoid: - That the discs come into direct contact with the ground.

-The compression of the springs.

-That the hydraulic hoses be properly capped.

Instruction Manual

Summary of Contents for CRI

Page 1: ...Drag Type Offset Disc Harrow Remote Control CRI 12 30...

Page 2: ......

Page 59: ...InstructionManual...

Page 62: ......

Page 64: ......

Page 67: ......