07

-

Allow

the

machine

to

dry

in

the

shade

so

that

it

does

not

accumulate

water

in

its

components.

Very

fast

drying

can

cause

stains

on

your

paint.

08

-

After

drying,

lubricate

all

chains

and

greases

according

to

the

recommendations

in

the

operator's

manual.

09

-

Spray

all

the

machine,

especially

the

zinc

parts,

with

protective

oil,

following

the

manufacturer's

application

guidelines.

The

protective

also

prevents

dirt

from

adhering

to

the

machine,

facilitating

subsequent

washings.

10

-

Observe

curing

(absorption)

time

and

application

intervals

as

recommended

by

the

manufacturer.

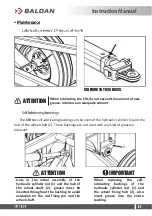

Do not use any other type of oil to protect the harrow (used

hydraulic oil, "burnt" oil, diesel oil, castor oil, kerosene, etc.).

ATTENTION

We recommend the following protective oils:

-

Bardahl: Agro protective 200 or 300

-

ITWChemical: Zoxol DW - Series 4000

IMPORTANT

Ignoring the conservation measures mentioned above may

result in the loss of warranty for painted or zinc-coated

components which may exhibit oxidation (rust).

OBSERVATION

06

- Do not use: - Detergents with a basic active ingredient (pH greater than 7), can

attack/stain the paint on the harrow.

- Detergents with acid active ingredient (pH less than 7), act as

stripper/remover of zinc coating (the protection of parts against

oxidation).

Instruction Manual

Summary of Contents for CRI

Page 1: ...Drag Type Offset Disc Harrow Remote Control CRI 12 30...

Page 2: ......

Page 59: ...InstructionManual...

Page 62: ......

Page 64: ......

Page 67: ......