CONDENSATION BOILER

AQUAKOND AKY

38

code HC0048.01GB ed.B-1406

AKY

8.

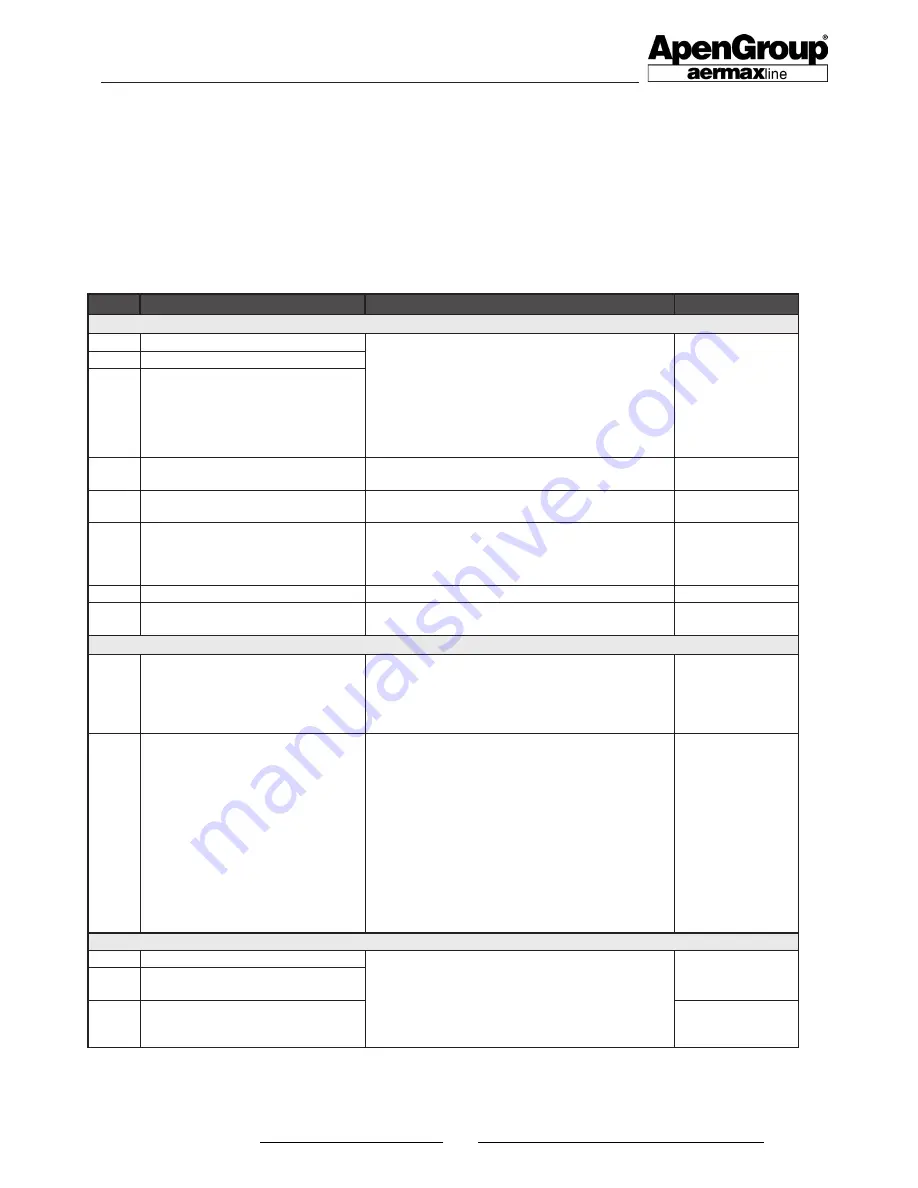

LOCK ANALYSYS - FAULT REPORTING

CPU-SMART board manages two types of locks:

- Precautionary: customer is warned that maintenance is required

- Operational: boiler is stopped for safety reasons.

Some of the locks require manual reset, others are automatically resolved when their cause is removed.

The following list shows all locks, their possible cause and remedy.

LOCK

DESCRIPTION

REASON

UNLOCK

Locks caused by flame / ACF device

F10

Start-up failure after 4 attempts.

•

Phase and neutral wires were exchanged.

•

Ground wire not connected

•

Phase-phase connection without neutral

•

Faulty or wrongly positioned start-up electrode

•

Faulty or wrongly positioned detection electrode

•

Detection electrode not properly fixed or discharged

to ground

•

Low CO2 value

Manual reset

F11

Ill-timed flame

F12

Start-up failure. Not shown.

Count in history indicates if the boiler

has problems in start-up phase.

F13

ACF device fails to accept CPU-SMART

board reset

TER device completed 5 reset attempts in 15 minutes. Wait 15 minutes or

reset the appliance.

F14

Communication failure for more than

60 seconds between ACF and CPU.

Damaged TER device or CPU-SMART board

Autoreset

F15

CPU-SMART board issued a start-up

signal to TER device but after 300

seconds the flame is not lit yet.

Faulty ACF device

Manual reset

F16

Generic lock

Faulty ACF device

Manual reset

F17

Internal problem with ACF device that

fails to accept CPU-SMART board reset. Faulty ACF device

Manual reset of de-

vice

Temperature locks (safety locks)

F20

STB safety thermostat triggers

•

Excessive water temperature because of insuf-

ficient circulation

•

Faulty or not connected safety thermostat

•

Faulty temperature sensor (NTC1) on water

delivery

Manual reset

F21

ID1 input contact is open because:

•

Heat exchanger thermal cut out

has triggered - TERM

•

ISPESL safety air pressure switch

has triggered - IP - (AKY070 only).

•

Water temperature in heat exchanger has ex-

ceeded safety limit of thermal cut-out. Uninstall

heat exchanger and inspect it to check that no

damages occurred. If it damaged, replace it.

•

Pressure in water circuit increased and IP MAXI-

ISPESL pressure switch has triggered, locking the

boiler. Check that all valves on the circuit are open.

•

Pressure in water circuit has fallen and IP MINI

ISPESL pressure switch has triggered, locking the

boiler; check that there are no water leaks on the

circuit and reset minimum pressure.

•

The expansion tank ran out of pressure, is too

small or it’s broken.

- Manual reset of

CPU-SMART

- If a pressure switch

is installed, it must

be manually reset,

as well.

Lock of burner fan

F30

Fan speed too low during start-up - VAG

Faulty burner fan.

- Faulty or not connected fan cables

Manual reset

F31

Fan speed too high during stand-by

- VAG

F32

Fan speed during operation exceeds

min and max parameters - VAG

Manual reset, au-

toreset after 5 min-

utes

Summary of Contents for AQUAKOND AKY

Page 2: ...CONDENSATION BOILER AQUAKOND AKY 2 code HC0048 01GB ed B 1406 AKY ...

Page 4: ...CONDENSATION BOILER AQUAKOND AKY 4 code HC0048 01GB ed B 1406 AKY 3 7 Approval Certificate ...

Page 5: ...CONDENSATION BOILER AQUAKOND AKY 5 code HC0048 01GB ed B 1406 AKY ...

Page 44: ...CONDENSATION BOILER AQUAKOND AKY 44 code HC0048 01GB ed B 1406 AKY ...