Section 7 — Maintenance • 41

Notice

Change the oil if the sample has any of the charac-

teristics listed in Figure 7.1.

If making a visual inspection, compare the sample of oil

to a sample of new oil of the same type. Also, compare

it to previous samples taken from the same unit. Look for

the signs of oil deterioration listed in Figure 7.1.

There are fluid contamination detector kits available

which allow for rapid, on-the-spot analysis of the hydraulic

system’s condition. Contact your Altec representative for

further information.

Oxidation produces varnishes that bake onto hot sur

-

faces. Oxidation products are acidic and tend to attack

metal surfaces. This can damage pumps, motors, and

valves. High operating temperatures will increase the

rate of oxidation of the oil. The presence of water or air

in hydraulic oil also causes oxidation.

The presence of water may cause rust and corrosion. If

laboratory analysis or visual inspection indicate that the

oil is deteriorating prematurely, determine the cause of

the problem and correct it.

Changing Oil and Flushing the System

A properly maintained filtration system greatly extends

the useful life of the hydraulic oil. However, the oil will

eventually need to be replaced due to contaminants that

form during normal operation of the unit.

It is impossible to recommend an exact time interval for

oil changes due to varying conditions of unit use. Use

the following guidelines to determine when the hydraulic

oil should be changed.

• Change the oil as recommended by the checklists

in the Appendix.

• If a hydraulic component fails and contaminates the

system with metallic particles, change the component

and the oil immediately.

• In climates with a wide variation in operating tempera

-

tures between summer and winter months, change

to the appropriate weight oil each spring and fall.

Replace the return line filter cartridge and filler breather

cap every time the hydraulic oil is changed. Also, clean

or replace the suction filter.

A significant quantity of oil remains in the hydraulic system

when the reservoir is drained. Flush the system when the

oil is changed. This is especially important if the system

is heavily contaminated with metal particles.

If the oil is contaminated with water, it may not be neces-

sary to change the oil and flush the system. Follow the

instructions under Water Removal in this section.

The following equipment and supplies are necessary to

properly flush the hydraulic system.

• Approximately 13 gallons (49 l) of proper hydraulic

oil

• Three return line filter cartridges

• Clean, lint-free rags

• Breather (if component has not been replaced

within one year)

Caution

Spilled hydraulic oil creates slick surfaces and can

cause personnel to slip and/or fall. Keep the unit and

work areas clean.

Use the following procedure to flush the hydraulic sys

-

tem.

1. If the oil is being changed because of contamination

due to hydraulic component failure, proceed to step

2. Otherwise, operate the unit to circulate the oil and

warm it to operating temperature. This will allow many

of the impurities to drain off in suspension.

2. Drain the oil reservoir completely.

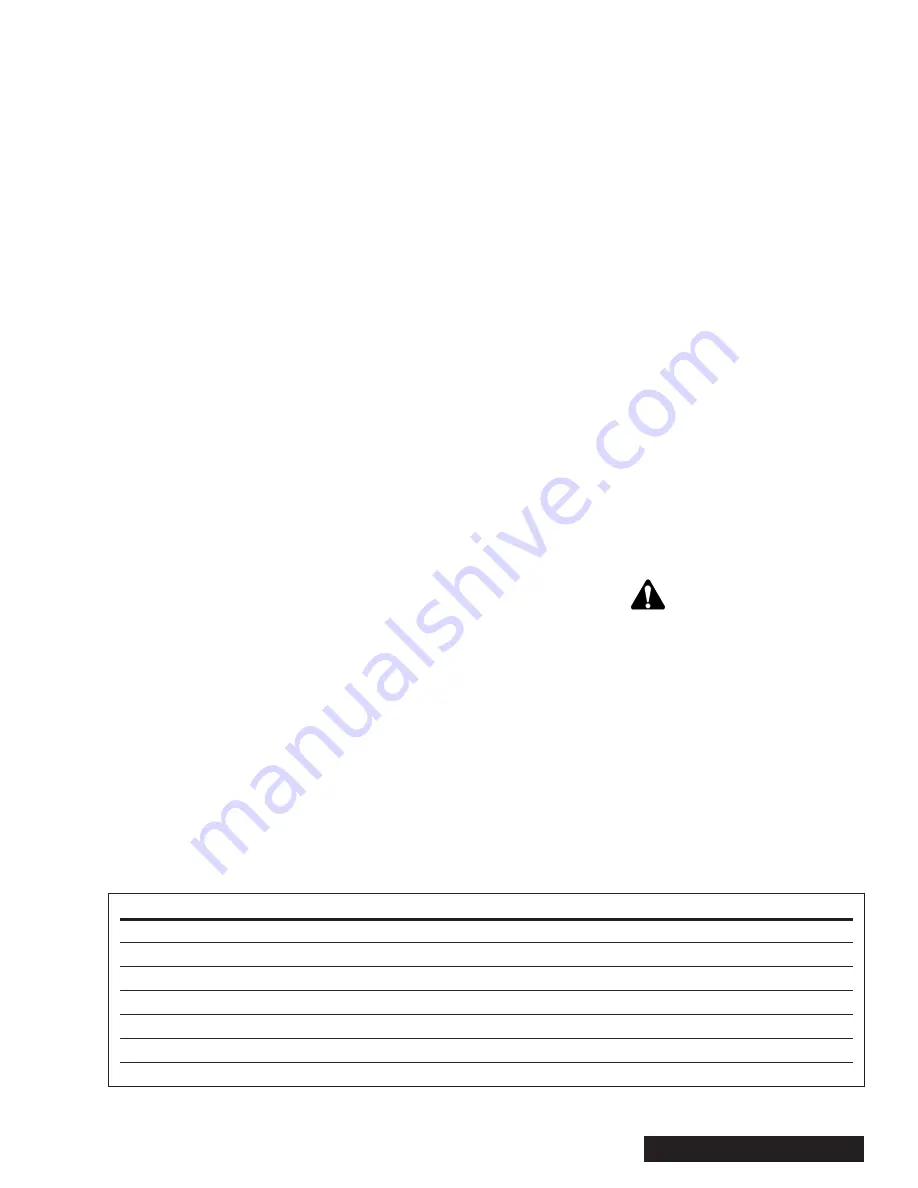

Figure 7.1 — Hydraulic Oil Conditions

Condition

Possible Cause

Dark color

Oxidation; contamination

Cloudiness or milky appearance

Presence of water or wax

Rancid or burned odor

Oxidation

Increase in viscosity

Oxidation; addition of improper fluids; presence of water

Decrease in viscosity

Addition of improper fluids; additive deterioration

Separation of water or other fluids from the oil

Presence of water; addition of improper fluids

Foreign particles or other visible contamination

Contamination; emulsion of water with oil additives

Summary of Contents for DRM 12

Page 3: ......

Page 7: ...2 Section 1 Introduction...

Page 17: ...12 Section 3 Safety Rear View Top View Bottom View 12 5 22 19 10 23 10 17 30 20 3 2 30...

Page 18: ...Section 3 Safety 13 4 8 7 2 3 970116658 1 6 5...

Page 19: ...14 Section 3 Safety 970116649 970116652 12 14 13 10 11 9...

Page 21: ...16 Section 3 Safety D G G D 25 26 24 27 23 22...

Page 22: ...Section 3 Safety 17 970137595 3X 30 31 28 29...

Page 23: ...18 Section 3 Safety...

Page 41: ...36 Section 6 Care of the Unit...

Page 62: ...Appendix...

Page 63: ......

Page 79: ...16 Appendix Glossary...

Page 83: ...Appendix Daily Preoperational Checklist...

Page 85: ...Appendix Preventive Maintenance and Inspection Checklist...

Page 88: ......

Page 89: ......

Page 91: ......

Page 93: ......

Page 96: ...07 13 970413443 A 2A PAGE 1 OF 2 ASSEMBLY FEED SYSTEM HYDRAULIC LIFT DRM 12...

Page 99: ...07 13 970413407 A 3A PAGE 1 OF 4 ASSEMBLY FEED CONTROL HYDRAULIC LIFT DRM 12...

Page 103: ...08 13 970485929 A 4A PAGE 1 OF 3 ASSEMBLY HAND CRANK CHUTE ROTATION DRUM CHIPPER...

Page 108: ...07 13 970413409 A 5A PAGE 1 OF 3 ASSEMBLY POWER SYSTEM KUBOTA 67 HP 74 HP 99 HP DIESEL DRM 12...

Page 113: ...07 13 970413438 A 6A PAGE 1 OF 4 FINAL ASSEMBLY DRM 12...

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 138: ...79A PAGE 1 OF 3 05 13 970457633 A ASSEMBLY FUEL SYSTEM DRM12 CFD1217...