37

T R A N SP O R T

—

Transport

6.1

MNS-Up section

• The MNS-Up sections must be shipped as individual sections, due to their dimensions and weight.

• ACB sections and MNS 3.0 sections may be shipped in sections of max 3 m in length or 3 sections. Shipping sections shall

only be transported in upright position

• For single empty sections, it is possible the to tilt the section carefully to side for transport, if the door height on site does

not allow upright transport

6.1.1

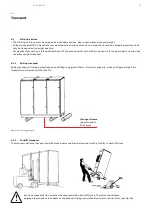

Rolling transport

Rolling transport of shipping sections up to 1200kg in weight with min. 3 rollers is possible. In case of higher weight, the

transport must be done with a forklift.

Figure 6-01 Rolling transport

6.1.2

Forklift transport

The transport pallets are supported with cross beams to allow the transport with a forklift or hand-lift truck

Sections may easily tip over when transported with a hand-lift truck. Therefore the distance

between the wooden cross beam or the pallet and the ground should not be more than 3 mm (see fig. 24).

!

Transport frame

(wooden beam

10 x 12 cm)

Summary of Contents for MNS-Up

Page 6: ... 01 Introduction ...

Page 8: ... 02 Safety first ...

Page 12: ... 03 General technical data ...

Page 16: ... 04 System description ...

Page 18: ... 05 Packing storage and transportation ...

Page 36: ... 06 Transport ...

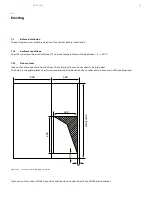

Page 40: ... 07 Erecting ...

Page 47: ...47 ERECTING ...

Page 48: ... 08 MNS Up configuration ...

Page 52: ... 09 MNS Up Module installation ...

Page 55: ...55 MNS UP MODULE INSTALL ATION ...

Page 56: ... 10 Handling of EMC boards ...

Page 59: ...59 HANDLING OF EMC BOARDS ...

Page 60: ... 11 Communication boards ...

Page 62: ... 12 MNS 3 0 sections ...

Page 64: ... 13 Commissioning ...

Page 66: ... 14 Operating of MNS Up system ...

Page 68: ... 15 Tightening torques for screw connection in MNS Up ...

Page 72: ... 16 Spare parts ...

Page 74: ... 17 Onsite inspection and maintenance ...

Page 76: ... 18 Maintenance intervals ...

Page 81: ...81 MAINTENANCE INTERVALS ...

Page 83: ......