67

O P ER AT I N G O F M N S - U P S Y S T EM

—

Operating of MNS-Up system

14.1

MNS-Up system operation

For operating instructions for the MNS-Up ups system please refere to the conceptpower DPA500 user manual

doc no 043275_OPM_ABB_CONCEPTPOWER_DPA_500kW_EN_REV-C.

14.2

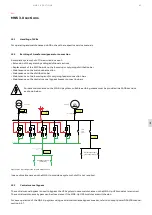

Handling/operating ACBs

For operating and maintenance on acbs check the respective service manuals supplied with the system.

14.3

Other electrical devices

User manuals are supplied for all electrical devices with the MNS-Up documentation package.

For operating and maintenance on any additional electrical device, please refer to the respective service manuals supplied

with the system.

Summary of Contents for MNS-Up

Page 6: ... 01 Introduction ...

Page 8: ... 02 Safety first ...

Page 12: ... 03 General technical data ...

Page 16: ... 04 System description ...

Page 18: ... 05 Packing storage and transportation ...

Page 36: ... 06 Transport ...

Page 40: ... 07 Erecting ...

Page 47: ...47 ERECTING ...

Page 48: ... 08 MNS Up configuration ...

Page 52: ... 09 MNS Up Module installation ...

Page 55: ...55 MNS UP MODULE INSTALL ATION ...

Page 56: ... 10 Handling of EMC boards ...

Page 59: ...59 HANDLING OF EMC BOARDS ...

Page 60: ... 11 Communication boards ...

Page 62: ... 12 MNS 3 0 sections ...

Page 64: ... 13 Commissioning ...

Page 66: ... 14 Operating of MNS Up system ...

Page 68: ... 15 Tightening torques for screw connection in MNS Up ...

Page 72: ... 16 Spare parts ...

Page 74: ... 17 Onsite inspection and maintenance ...

Page 76: ... 18 Maintenance intervals ...

Page 81: ...81 MAINTENANCE INTERVALS ...

Page 83: ......