26

M N S - U P

SER V I C E M A N UA L

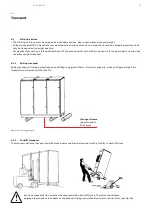

5. Miralon 2 mm is placed all over the shipping section and is stripped by tape. The tape is supported by plastic edge

protection.

!

A drying agent is required for seaworthy packing. A single packet 32 DIN is required per 3 m

2

box.

Figure 5-07 Seaworthy packing procedure, steps 4 & 5

6. The shipping section is sealed in AL foil and the air is extracted. The unit is then wrapped by plastic film

to strengthen the wrap.

30%

50%

40%

AL foil

Location of

humidity detector

Transport section wraped

with plastic foil

Summary of Contents for MNS-Up

Page 6: ... 01 Introduction ...

Page 8: ... 02 Safety first ...

Page 12: ... 03 General technical data ...

Page 16: ... 04 System description ...

Page 18: ... 05 Packing storage and transportation ...

Page 36: ... 06 Transport ...

Page 40: ... 07 Erecting ...

Page 47: ...47 ERECTING ...

Page 48: ... 08 MNS Up configuration ...

Page 52: ... 09 MNS Up Module installation ...

Page 55: ...55 MNS UP MODULE INSTALL ATION ...

Page 56: ... 10 Handling of EMC boards ...

Page 59: ...59 HANDLING OF EMC BOARDS ...

Page 60: ... 11 Communication boards ...

Page 62: ... 12 MNS 3 0 sections ...

Page 64: ... 13 Commissioning ...

Page 66: ... 14 Operating of MNS Up system ...

Page 68: ... 15 Tightening torques for screw connection in MNS Up ...

Page 72: ... 16 Spare parts ...

Page 74: ... 17 Onsite inspection and maintenance ...

Page 76: ... 18 Maintenance intervals ...

Page 81: ...81 MAINTENANCE INTERVALS ...

Page 83: ......