Repairs

Motors and Gears Axes 4-6

Product Manual IRB 6400R

15

4 Motors and Gears Axes 4-6

4.1 Motor axis 4

Refer to foldout 2:10

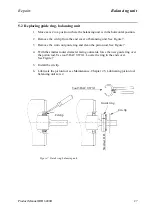

Dismounting:

1.

Drain the gearbox by removing oil plugs <48>.

2.

Secure axis 4 so it cannot rotate when the motor is removed.

3.

Attach a hoist and the lifting device (3HAC 3HAC 6875-1) to the motor

4.

Release the breaks so it will be possible to pull and turn the motor out and minimise

the risk of damaging the pinion (see 2.5 Manually releasing the brakes).

5.

Unscrew the 4 cable inlet cover screws.

6.

Unscrew the 3 screws on the top of motor 4. Remove the cover.

7.

Disconnect connectors R2.MP4 and R2.FB4.

Be careful not to tap or hit the shaft axially, nor displace the shaft axially in any way,

as this could give rise to an incorrect air gap in the brake.

8.

To press the gear off the motor shaft, oil must be injected into the centre of the gear.

Mount SKF Oil injector SKF nipple 725 870 + 234 063 in the centre and

press the gear off the shaft.

Caution: Make sure that the oil injector is filled with oil.

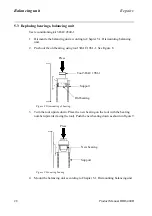

Mounting:

9.

Remove the B-side cover at the rear of the motor and place support 3HAA 7601-070

under the motor shaft, to avoid axial loading of the bearings in the motor.

10.

Clean the pinion hole on the motor with Ethanol, art. no. 1177 1012-205 and dry with

a clean piece of paper.

11.

Clean the pinion shaft in the same way.

12.

Apply some mineral oil (BP-CS 320) on the pinion shaft and in the pinion hole on the

motor. Wipe off any surplus with paper, leaving a thin film of oil on the surfaces.

13.

Press the gear on to the motor shaft with a minimum pressure of 250 bar (corresponds

to a press force of 1.5-2 t). Use tools 3HAA 7601-070 and 3HAB 5674-1.

14.

If the pressure is less than 250 bar or if the pinion “jumps” in intermittently, the pin-

ion must be removed, cleaned, and oiled again before mounting.

15.

The total indicated runout of the pinion must not be more than 0.01 mm.

16.

Reconnect connectors R3.MP4 and R3.FB4. Mount the cover.

17.

Release the breaks, mount O-ring <49> and insert the motor. Turn the motor carefully

so that the pinion and the gears in the gearbox mesh together.

18.

Apply Loctite 243 and tighten screws <25>, torque 24 Nm.

19.

Fill the gearbox with oil, type ABB 1171 2016 -604, volume 6 litres. Regarding

replacement oils see the Maintenance Manual IRB 6400R.

20. Calibrate the robot as described in Chapter 9, Calibration.

Summary of Contents for IRB 6400R

Page 4: ...Description 20 Product Specification IRB 1400 M97A BaseWare OS 3 0 ...

Page 6: ...Introduction 2 Product Manual ...

Page 10: ...Introduction 6 Product Manual ...

Page 12: ...Product Specification IRB 6400R 2 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 78: ...Accessories 68 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 80: ...Product Specification RobotWare 2 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 82: ...Introduction 4 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 104: ...Interbus S 3 2 26 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 110: ...I O Plus 3 2 32 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 128: ...PalletWare 50 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 132: ...Safety 2 Product Manual ...

Page 148: ...System Description CONTENTS Page 2 Product Manual ...

Page 158: ...Structure System Description 12 Product Manual ...

Page 160: ...Computer System System Description 14 Product Manual ...

Page 164: ...I O System System Description 18 Product Manual ...

Page 168: ...Safety System System Description 22 Product Manual ...

Page 170: ...External Axes System Description 24 Product Manual ...

Page 174: ...Installation and Commissioning CONTENTS Page 4 Product Manual IRB 6400R ...

Page 196: ...On Site Installation Installation and Commissioning 26 Product Manual IRB 6400R ...

Page 270: ...Installing the Control Program Installation and Commissioning 100 Product Manual IRB 6400R ...

Page 292: ...Maintenance CONTENTS Page 2 Product Manual IRB 6400R ...

Page 299: ...Maintenance Product Manual IRB 6400R 9 Figure 4 Lubricating gearbox axis 1 4 3 1 2 ...

Page 312: ...Troubleshooting Tools CONTENTS Page 2 Product Manual ...

Page 350: ...Troubleshooting Tools 40 Product Manual ...

Page 352: ...Fault tracing guide 2 Product Manual ...

Page 362: ...Fault tracing guide 12 Product Manual ...

Page 375: ...Motor units Repairs 12 Product Manual IRB 6400R ...

Page 401: ...Arm System Repairs 38 Product Manual IRB 6400R ...

Page 409: ...Cabling Repairs 46 Product Manual IRB 6400R ...

Page 441: ...Special Tools List Repairs 80 Product Manual IRB 6400R ...

Page 479: ...Part List and Spare Parts Product Manual IRB 6400R 38 ...

Page 480: ...Part List and Spare Parts Product Manual IRB 6400R 39 ...

Page 481: ...Part List and Spare Parts Product Manual IRB 6400R 40 ...