7

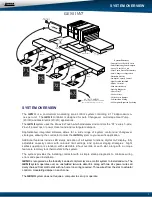

General Installation Instructions

GEN II Controller

1. Install the

GEN II

controller on an interior wall where the ambient temperature is between 32°-

120°F (0°- 48°C) non-condensing. This controller is to be installed in an accessible interior

area; not in attics or above ceilings.

2. The controller is to be powered by a

dedicated

24vac 100va transformer. The transformer seco-

ndary is wired to

TR1 TR2

on the controller

(B).

The secondary voltage to the controller must be

3. Install the LAT air sensor in the supply air between the indoor coil and electric strip heat

elements.

4. The leaving air sensor (LAT) is calibrated to the controller at the factory. However, the

calibration should be checked as part of the system setup procedures. If adjustments are

required, use the Blue potentiometer labeled R44 located in the upper left hand corner of the

GEN II

controller. Screw the pot clockwise to lower the display temperature and counter -

clockwise to raise the temperature.

NOTE

: The display will update every 10 seconds.

Heat Pump operation “O” reversing valve

Cool Call – When a majority active cool call is received by the

GEN II

controller, Y1, O/B and G

LEDs are illuminated; and the outputs are energized (within 1.5 to 3 minutes). After 3 minutes, if

the leaving air temperature is 58°F (14°C) or above, Y2 will energize for 2-stage systems. Y2 will

de-energize when it drops below 50°F and re-energize when it rises above 58°F. If the supply air

temperature drops one degree below the Cool cut-out temperature, Y1 and Y2 will de-energize

“B” reversing valve – Sequence of operation is the same: O/B is energized in the heat mode.

Heat Call - When a majority active heat call is received by the

GEN II

controller, Y1 and G LEDs are

illuminated; and the outputs are energized (within 1.5 to 3 minutes). If after 3 minutes the leaving

air temperature is 94°F (34°C) or less, Y2 will energize. If after 6 minutes of run time the leaving air

temperature is 91°F (32°C) or less, W2 will energize. If the supply air temperature exceeds 126°F

(52°C), Y1, Y2 and W2 (if energized) will drop out; and Y1 can then energize after a 5-minute time

delay. NOTE: If the system fan is configured for “AUTO” on the

GEN II

controller, the “G” output

will be de-energized in the temperature cut-out mode.

When the last active call satisfies, the

GEN II

controller goes into a 5-minute purge cycle with all

supply dampers closing; then all dampers modulate open for ventilation.

GENERAL INSTALLATION INSTRUCTIONS

5. Confirm you have connected the

A

and

B

communication wires and

TR1

and

TR2

from the

thermostats to the Gen II controller (

A & L

), A=(TR1, TR2), L=(A, B). (Communication wire

maximum is 4,000 ft. from the Gen II controller to the farthest EzTouch).

6. Connect the output wires from the controller to the HVAC system using standard 18 GA

thermostat wire.

The LAT sensor leads may be extended using standard 18/2 thermostat wire.

for 5 minutes.

Heat Pump operation “B” reversing valve

By placing the O/B jumper (B) on both pins, the

GEN II

controller is configured for “B” reversing

valve operation. The operation and setup procedures are the same as with “O” mode reversing

valve, except the reversing valve will be energized for heat operation.

24 to 28vac.

DO NOT ground out the transformer

.