5

2.

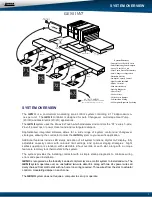

O/B

and

HP

jumpers

(F)

should both be on one pin or removed, for GE operation.

3.

PRIORITY

jumper

(F)

should be on one pin.

Note: If the Priority opposing call strategy is to be used, this jumper position will be changed

after the initial system start-up is completed.

See Advanced Feature Configuration.

4. Set the power switch

(E)

to

ON

.

5. Set the

NIGHT DAY

switch

(J)

to the

DAY

position.

6. Set the fan jumper

(I)

to

AUTO

for intermittent operation or

ON

for constant ON operation in the

Occupied mode.

7. Place the

LOCK

–

UNLOCK

switch

(K)

in the UNLOCK position.

8. Place the

TIME/TEMP

jumper

(I)

on the middle and upper pins to control Y2 and W2 staging on

run time and supply air temperature.

GEN II

Gas Electric Advanced Feature Configuration

Gas Electric Capacity Control - Cool and Heat cut-out temperature adjust

The factory setting for the Cool and Heat cut-out temperatures is 45°- 145°F (7°- 62°C). This can

be easily changed with the following procedure:

1.

Cool cut-out temp

– Press the DN button

(H)

; “C” will be displayed and then the cut-out

temperature.

2. LOWER – Press the DN button; after the “C” is displayed, continue to hold the DN button until

the desired temperature is displayed; then release.

NOTE: The controller will not change the Cool cut-out lower than 40°F (4°C).

3. RAISE – Press the DN button; after “C” is displayed, immediately release the DN button and

press the UP button. Hold until the desired temperature reading is displayed and release.

4. Press the DN button to verify the new cool cut-out temperature.

Heat cut-out temperature

- Press and hold the UP button; after the “H” is displayed, use the

same procedure as above to raise or lower the displayed temperature.

Electric Heat - Fan Configuration

EH

jumper

(F)

is installed by the factory on one pin for normal gas heat operation where the fan is

controlled by the HVAC system fan control. When a fan output is required from the

GEN II

controller on a call for heat, place the

EH

jumper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

Adjust 2

nd

Stage Cut-in Time Delay

1. To increase the Y2 and W2 cut-in delay, press and hold the SET and DN buttons

(H)

simultaneously. When 03 appears in the display, release the buttons and immediately press

the UP button and hold until the desired delay time is displayed, and release. The time delay

is fully adjustable from 3 - 20 minutes. To verify the change, press and hold the SET and DN

buttons simultaneously until the delay time is shown, and release.

GAS ELECTRIC ADVANCED FEATURE CONFIGURATION

2nd Stage Heat and Cool Cut-in / Cut-out Configuration

The GEN II controller is set up at the factory to stage Y2 and W2 cut-in operation based on a 3-minute

time delay and supply air temperature. This is done using the TIME/TEMP (I) jumper. Time may be

field configured from 3-20 minutes by the contractor during system configuration. The cut-in tempera-

tures are fixed in the controller program at 58°F (14°C) and higher for Y2 and 120°F (48°C) and lower

for W2. The GEN II controller second stage cut-out temperature is fixed in the controller program at

50°F (10°C). Y2 will de-energize when it drops below 50°F and re-energize when it rises above 58°F.

If the air temperature drops below the low cut-out (45°F) Y1 and Y2 are de-energized and the control-

ler will go into a 5 minute purge mode. After 5 minute purge, if the temperature has risen above the

low cut-out Y1 is re-energized. Heat W1 and W2 will de-energize if leaving air temperature rises above

heat cutout and will be locked out for 5 minutes. After 5 minute lockout, if a heat call remains and

leaving air temperature is lower than heat cutout, W1 will re-energize. By placing jumper on bottom

two pins, a time only strategy may be configured into the system. ( see below);