Page - 34/95

AEMZP0BA - EPS-AC0 - User Manual

U

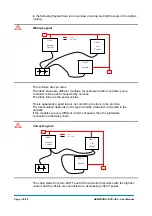

A cable connected to the wrong pin can lead to short circuits and failure; so,

before turning on the truck for the first time, verify with a multimeter the

continuity between the starting point and the end of a signal wire.

8.8 Safety features

U

ZAPI controllers are designed according to the prEN954-1 specifications for

safety related parts of control system and to UNI EN1175-1 norm. The safety of

the machine is strongly related to installation; length, layout and screening of

electrical connections have to be carefully designed.

ZAPI is always available to cooperate with the customer in order to evaluate

installation and connection solutions. Furthermore, ZAPI is available to

develop new SW or HW solutions to improve the safety of the machine,

according to customer requirements.

Machine manufacturer holds the responsibility for the truck safety features

and related approval.

Eps-ac0 implements a double µC structure to comply with the Category#3

specification. The second µC main task is to check correct functionality of the first

µC, whose main task is to control the steering motor. Basically, the two

microcontrollers implement a double check control of the main functions.

The two µCs are both CAN Bus connected. This characteristic makes possible the

eps-ac0 receives the steering command (wished steered wheel position) via CAN

Bus fulfilling the norm.

8.9 EMC

U

EMC and ESD performances of an electronic system are strongly influenced

by the installation. Special attention must be given to the lengths and the

paths of the electric connections and the shields. This situation is beyond

ZAPI's control. Zapi can offer assistance and suggestions, based on its years

experience, on EMC related items. However, ZAPI declines any responsibility

for non-compliance, malfunctions and failures, if correct testing is not made.

The machine manufacturer holds the responsibility to carry out machine

validation, based on existing norms (EN12895 for industrial truck; EN50081-2

for other applications).

EMC stands for Electromagnetic Compatibility, and it represents the studies and the

tests on the electromagnetic energy generated or received by an electrical device.

Emission

refers to the energy radiated from the controller and the harness.

Immunity

can be divided in two main branches: rejection from external

electromagnetic fields and from electrostatic discharges (ESD).

So the analysis works in three directions:

Содержание EPS-AC0

Страница 23: ...AEMZP0BA EPS AC0 User Manual Page 23 95 6 2 EPS AC0 Stepper Motor diagram Figure 6 2...

Страница 24: ...Page 24 95 AEMZP0BA EPS AC0 User Manual 6 3 EPS AC0 Twin pot diagram Figure 6 3...

Страница 54: ...Page 54 95 AEMZP0BA EPS AC0 User Manual 12 3 1 Stepper motor with Encoder and Feedback pot Figure 12 2...

Страница 55: ...AEMZP0BA EPS AC0 User Manual Page 55 95 12 3 2 RTC with Encoder and Feedback pot Figure 12 3...

Страница 56: ...Page 56 95 AEMZP0BA EPS AC0 User Manual 12 3 3 Stepper motor with Encoder and Toggle switch es Figure 12 4...