JOHNSON CONTROLS

36

FORM 150.67-NM2 (209)

Installation

DUCT WORK CONNECTION

General Requirements

The following duct work recommendations are

intended to ensure satisfactory operation of the unit.

Failure to follow these recommendations could cause

damage to the unit, or loss of performance, and may

invalidate the warranty.

When ducting is to be

fi

tted to the fan discharge it

is recommended that the duct should be the same

cross-sectional area as the fan outlet and straight for

at least three feet (1 meter) to obtain static regain

from the fan. Duct work should be suspended with

fl

exible hangers to prevent noise and vibration being

transmitted to the structure. A

fl

exible joint is also

recommended between the duct attached to the fan

and the next section for the same reason. Flexible

connectors should not be allowed to concertina.

The unit(s) is not designed to take structural loading.

No signi

fi

cant amount of weight should be allowed

to rest on the fan outlet

fl

ange, deck assemblies or

condenser coil module. No more than 3 feet (1 meter)

of light construction duct work should be supported

by the unit. Where cross winds may occur, any duct

work must be supported to prevent side loading on the

unit.

If the ducts from two or more fans are to be combined

into a common duct, back-

fl

ow dampers should be

fi

tted in the individual fan ducts. This will prevent re-

circulation of air when only one of the fans is running.

Units are supplied with outlet guards for safety and

to prevent damage to the fan blades. If these guards

are removed to

fi

t duct work, adequate alternative

precautions must be taken to ensure persons cannot be

harmed or put at risk from rotating fan blades.

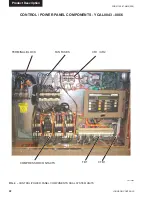

WIRING

Liquid Chillers are shipped with all factory-mounted

controls wired for operation.

Field Wiring –

Power wiring must be provided through

a fused disconnect switch to the unit terminals (or

optional molded disconnect switch) in accordance with

N.E.C. or local code requirements. Minimum circuit

ampacity and maximum dual element fuse size are

given in Tables 6.

Copper power wiring only should be used for supplying

power to the chiller. This is recommended to avoid safety

and reliability issues resulting from connection failure at

the power connections to the chiller. Aluminum wiring

is not recommended due to thermal characteristics

that may cause loose terminations resulting from the

contraction and expansion of the wiring. Aluminum

oxide may also build up at the termination causing hot

spots and eventual failure. If aluminum wiring is used

to supply power to the chiller, AL-CU compression

fi

ttings should be used to transition from aluminum to

copper. This transition should be done in an external

box separate to the power panel. Copper conductors

can then be run from the box to the chiller.

A 120-1-60, 15 amp source must be supplied for the

control panel through a fused disconnect when a control

panel transformer (optional) is not provided (Refer to

FIG. 8).

See unit wiring diagrams for

fi

eld and power wiring

connections, chilled water pump starter contacts,

alarm contacts, compressor run status contacts, PWM

input, and load limit input. Refer to section on UNIT

OPERATION for a detailed description of operation

concerning aforementioned contacts and inputs.

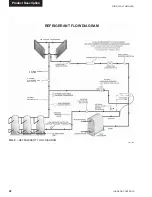

Evaporator Pump Start Contacts

Terminal block TB1 – terminals 23 to 24, are nor mally-

open contacts that can be used to switch

fi

eld supplied

power to provide a start signal to the evapo rator pump

contactor. The contacts will be closed when any of the

following conditions occur:

1. Low Leaving Chilled Liquid Fault

2. Any compressor is running

3. Daily schedule is not programmed OFF and the

Unit Switch is ON

The pump will not run if the micro panel has been

powered up for less than 30 seconds, or if the pump

has run in the last 30 seconds, to prevent pump motor

overheating. Refer to FIG. 9 and unit wiring dia gram.

System Run Contacts

Contacts are available to monitor system status.

Normally-open auxiliary contacts from each com pressor

contactor are wired in parallel with TB1 – terminals 25

to 26 for system 1, and TB1 – termi nals 27 to 28 for

system 2 (YCAL0043 - YCAL0066). Refer to FIG. 4,

9 and unit wiring diagram.

Содержание YCAL0019

Страница 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Страница 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Страница 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Страница 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Страница 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Страница 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Страница 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...