FORM 150.67-NM2 (209)

169

JOHNSON CONTROLS

8

CONFIGURATION (JUMPERS AND

POTENTIOMETERS)

Each VFD is pre-con

fi

gured at the factory prior to

shipping and should be ready for operation when

it arrives onsite. A quick check of the settings is

recommended. The jumpers must be in the positions

shown in the following Tabl

e.

VFD JUMPERS

J2

REMOVE

—

J3

IN

—

J4

REMOVE

—

J5

IN

—

J6

IN

—

J7

IN

—

J8

IN

—

J9

IN FOR 60 HZ

REMOVE FOR 50 HZ

Potentiometer settings are also preset at the factory.

The potentiometers should be in the positions shown

in the following table. The pots do not have numerical

settings and are set according to the arrow positions

indicated. DO NOT change the potentiometer

settings unless they do not match the positioning of

the potentiometers shown in Fig. 29. P1 should be

full CW (292 PSIG) and P2 should be full CCW (32

PSIG).

Modifying these settings may cause damage to

the chiller or control problems.

The P1 pot sets the setpoint which is the top end of the

control range. This setting is the discharge pressure at

which the fan will be operating at full speed. The P2

pot sets the range. This is the range of pressure where

the VSD modulates the fan speed from 0 RPM to full

speed. The range is subtracted from the setpoint to

calculate the 0 RPM pressure.

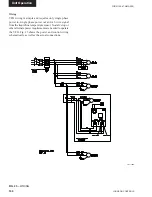

Wiring

VFD wiring is simple and requires only 3-phase power

in, 3-phase power out, and a 2-wire signal from the

transducer. No start, stop, or other alternate power

requirements are needed to run the VFD. Fig’s 28 and

29 show the power and control wiring schematically

as well as the actual connections. The VFD controlled

fan will operate whenever the liquid line solenoid on

the respective system is energized

P1

P2

P1

P2

POTENTIOMETER SETTINGS

P1

P2

292 PSI

32 PSI

FIG. 29 –

POTENTIOMETER SETTINGS

LD11300A

FIG. 28 –

INVERTER POWER WIRING SCHEMATIC

LD11301a

150A

L1

T1

150

151A

L2

T2

151

152A

L3

T3

152

CONDENSER

FAN NO. 1

SPEED

CONTR.

7M

YCAL0033 PROGRAMMING

Condenser fan control type must be programmed under

both the OPTIONS and PROGRAM keys when an VFD

is installed on the chiller. Under the OPTIONS key, FAN

CONTROL must be programmed for DISCHARGE

PRESSURE CONTROL only. This will assure the

condenser fan control is solely by discharge pressure

with no ambient control.

Under the PROGRAM key, the FAN CONTROL ON

PRESSURE should be programmed for 425 PSIG

and the FAN DIFFERENTIAL OFF PRESSURE

should be programmed for 125 PSIG.

Содержание YCAL0019

Страница 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Страница 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Страница 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Страница 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Страница 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Страница 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Страница 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...