RT70 Operator’s Manual

Maintenance - 191

Trencher Procedures

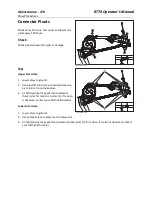

Headshaft Motor Shaft

Check headshaft motor shaft (shown) every 10

hours.

1. Check headshaft for wire or string wrapped

around shaft at seal.

2. Carefully removed wrapped material.

3. Check for oil leaking from shaft seal.

4. If oil is leaking from motor shaft seal, check

motor shaft for looseness in bearings.

5. Remove and replace motor if bearings are

loose enough to allow oil to leak from seal.

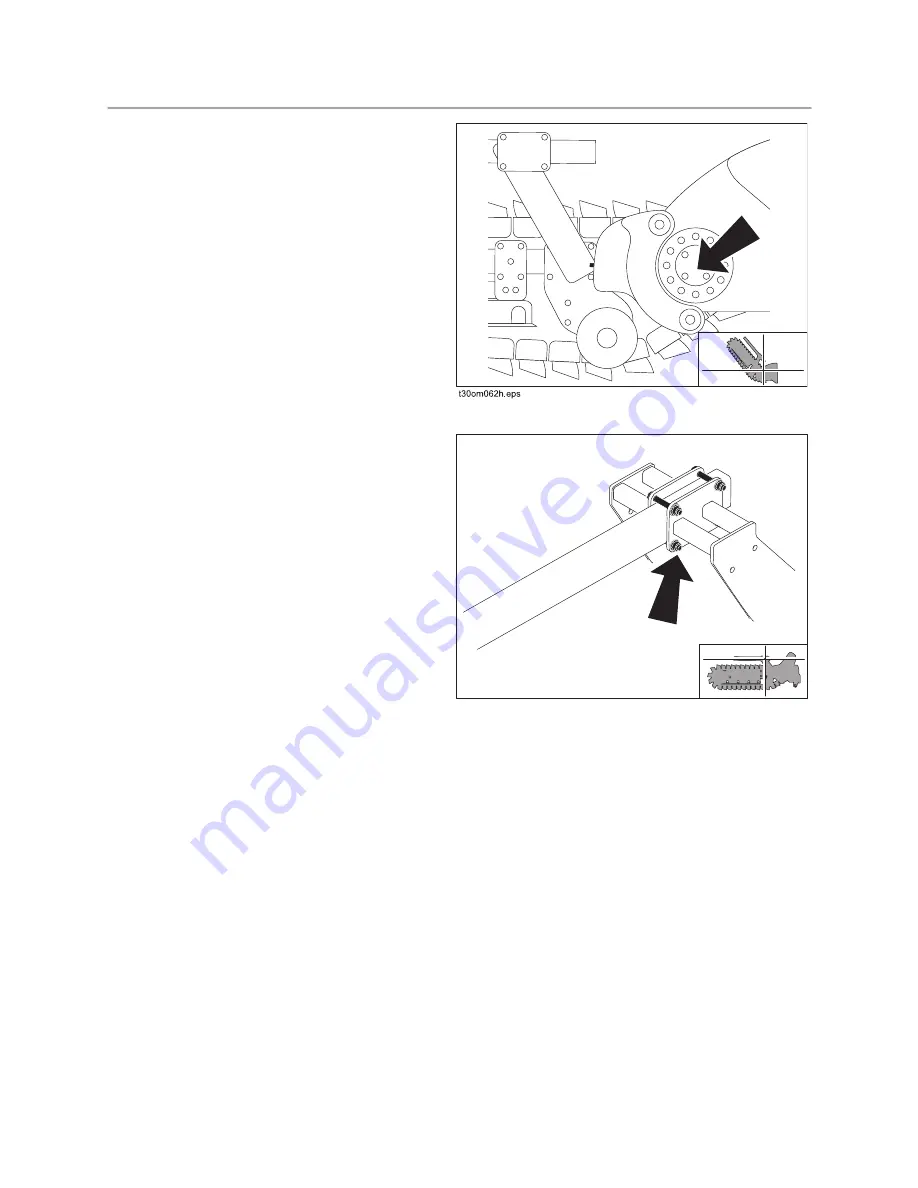

Personnel Restraint Bar/

Trench Cleaner Bolts

Check all bolts securing restraint bar/trench

cleaner to arm (4 on each side, shown) and arm to

boom every 10 hours.

Check all bolts securing restraint bar/trench

cleaner to machine every 10 hours.

1. Check for looseness or wear.

2. Apply Loctite® 271.

3. Tighten bolts holding personnel restraint bar/

trench cleaner (shown) to 350ft•lb (475N•m).

4. Tighten bolts securing arm to boom to 400ft•lb (542N•m).

t63om070h21.eps

t63om070h21.eps

Содержание RT70

Страница 9: ...Overview 8 RT70 Operator s Manual About This Manual ...

Страница 19: ...Safety 18 RT70 Operator s Manual Emergency Procedures ...

Страница 31: ...Safety 30 RT70 Operator s Manual Attachment Safety Alerts ...

Страница 83: ...Controls 82 RT70 Operator s Manual Seat ...

Страница 89: ...Drive 88 RT70 Operator s Manual Shut Down ...

Страница 97: ...Transport 96 RT70 Operator s Manual Haul ...

Страница 103: ...Backhoe 102 RT70 Operator s Manual Finish Job ...

Страница 123: ...Reel Carrier 122 RT70 Operator s Manual Finish Job ...

Страница 129: ...Trench 128 RT70 Operator s Manual Finish Job ...

Страница 141: ...Systems and Equipment 140 RT70 Operator s Manual Counterweights ...

Страница 145: ...Maintenance 144 RT70 Operator s Manual Trencher Maintenance Interval Chart 183 Trencher Procedures 184 ...

Страница 221: ...Specifications 220 RT70 Operator s Manual EU Declaration of Conformity ...