Maintenance - 186

RT70 Operator’s Manual

Trencher Procedures

Digging Chain

Check every 10 hours. Change digging chain as needed.

Check

Bits

1. If using rock chain bits, check that bits rotate

freely.

2. Clean chain and check bits after each use.

3. Replace bit when carbide cap or insert is

worn.

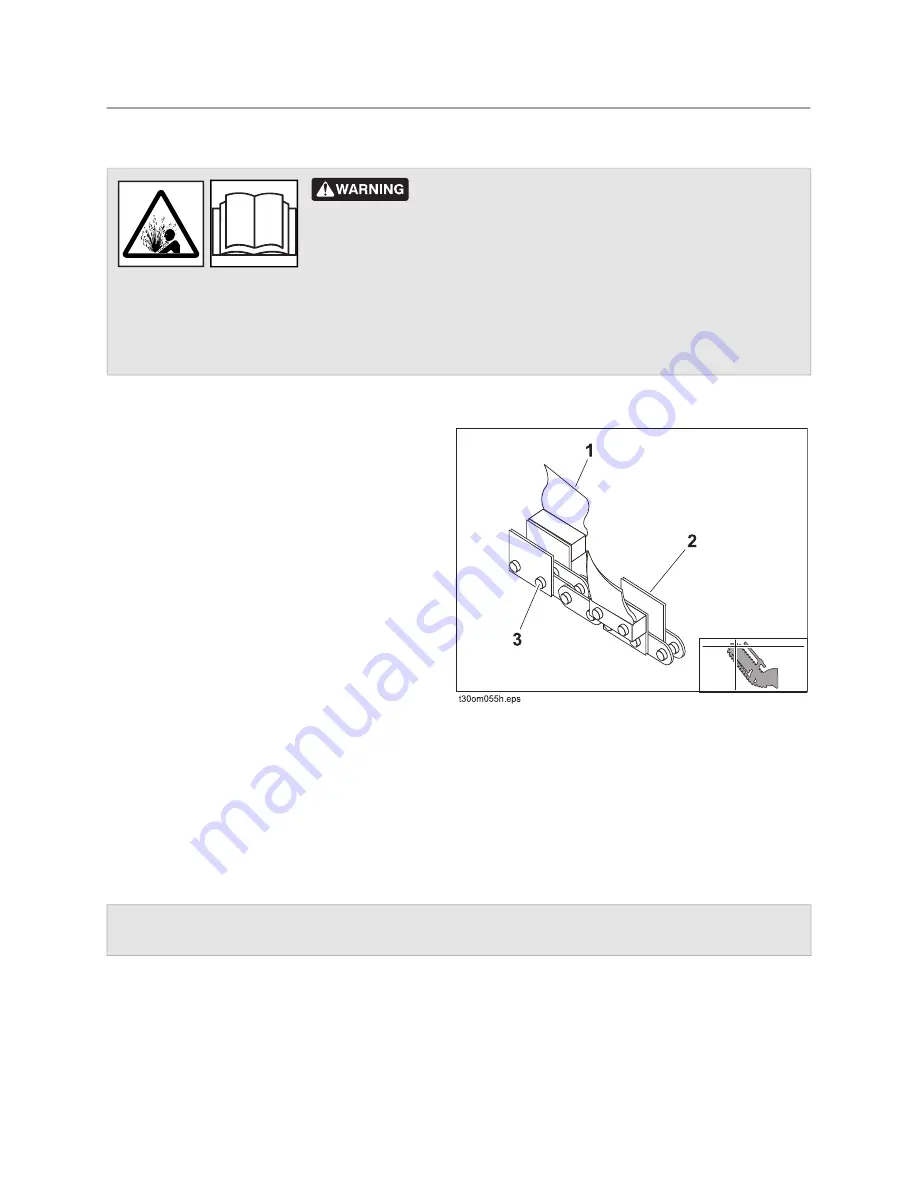

Pins and Bushings

Check pins and bushings for wear by measuring

distance between chain pins (3) and comparing it

with a new chain.

Sidebars

If sidebars (2) are bent or loose on chain pins, chain spacers should be used to join sidebars.

Teeth

Check teeth (1) for wear.

Contents under pressure. Impact can cause death or

serious injury. Relieve pressure before opening.

To help avoid injury:

• Service digging boom grease cylinder only while standing on opposite side of boom.

• Cover connection with heavy cloth when relieving pressure in cylinder.

NOTICE:

Replace worn teeth using Ditch Witch replacement parts and maintaining original tooth

pattern.

Содержание RT70

Страница 9: ...Overview 8 RT70 Operator s Manual About This Manual ...

Страница 19: ...Safety 18 RT70 Operator s Manual Emergency Procedures ...

Страница 31: ...Safety 30 RT70 Operator s Manual Attachment Safety Alerts ...

Страница 83: ...Controls 82 RT70 Operator s Manual Seat ...

Страница 89: ...Drive 88 RT70 Operator s Manual Shut Down ...

Страница 97: ...Transport 96 RT70 Operator s Manual Haul ...

Страница 103: ...Backhoe 102 RT70 Operator s Manual Finish Job ...

Страница 123: ...Reel Carrier 122 RT70 Operator s Manual Finish Job ...

Страница 129: ...Trench 128 RT70 Operator s Manual Finish Job ...

Страница 141: ...Systems and Equipment 140 RT70 Operator s Manual Counterweights ...

Страница 145: ...Maintenance 144 RT70 Operator s Manual Trencher Maintenance Interval Chart 183 Trencher Procedures 184 ...

Страница 221: ...Specifications 220 RT70 Operator s Manual EU Declaration of Conformity ...