Maintenance - 172

RT70 Operator’s Manual

Microtrencher Procedures

Wear Bars/Hard-Surface Material

Check thickness of wear bars and hard-surface

material with gauge (shown, 301-1507). Replace

material as needed.

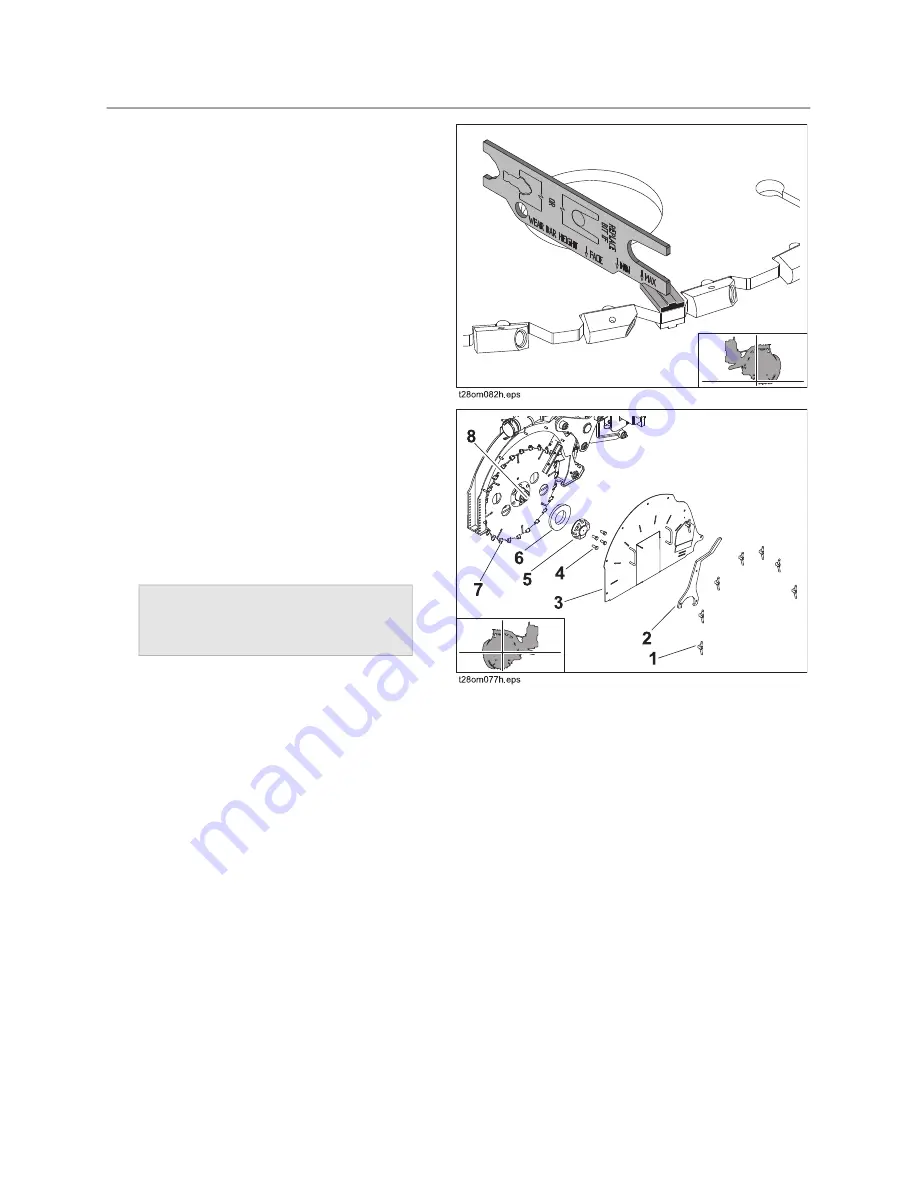

Change Blade

1. Start engine.

2. Position microtrencher slightly above ground.

3. Shut off ma hine.

4. Remove 7 wingnuts (1), spanner wrench (2),

and cover (3).

5. Loosen clamp bolts (4) and remove large nut

(5).

6. Remove spacer (6) and blade (7).

7. Clean threads on hub (8) and nut (6). If needed, apply dry lubricant such as graphite or silicone to

threads.

8. Install new blade (note direction of rotation), spacer and large nut.

9. Fully tighten large nut.

10. Tighten clamp bolts to 100-120ft•lb (135-160N•m).

11. Loosen clamp bolts and repeat steps 8 and 9.

12. Install cover, spanner wrench, and wingnuts.

IMPORTANT:

To keep blade from

turning, insert prybar through cutout

in blade.

Содержание RT70

Страница 9: ...Overview 8 RT70 Operator s Manual About This Manual ...

Страница 19: ...Safety 18 RT70 Operator s Manual Emergency Procedures ...

Страница 31: ...Safety 30 RT70 Operator s Manual Attachment Safety Alerts ...

Страница 83: ...Controls 82 RT70 Operator s Manual Seat ...

Страница 89: ...Drive 88 RT70 Operator s Manual Shut Down ...

Страница 97: ...Transport 96 RT70 Operator s Manual Haul ...

Страница 103: ...Backhoe 102 RT70 Operator s Manual Finish Job ...

Страница 123: ...Reel Carrier 122 RT70 Operator s Manual Finish Job ...

Страница 129: ...Trench 128 RT70 Operator s Manual Finish Job ...

Страница 141: ...Systems and Equipment 140 RT70 Operator s Manual Counterweights ...

Страница 145: ...Maintenance 144 RT70 Operator s Manual Trencher Maintenance Interval Chart 183 Trencher Procedures 184 ...

Страница 221: ...Specifications 220 RT70 Operator s Manual EU Declaration of Conformity ...