8

9

NAVIGATING THE RUN SCREEN

When in the Run screen, the up and down arrow keys will move the

highlighted box along the bottom options. Once a box is highlighted,

press enter to access the highlighted option.

Description of Run screen box functions from left to right:

Option

Description

Barometer

Highlight and press enter to calibrate the

instrument’s internal barometer.

Salinity Value

Highlight and press enter to adjust the salinity

compensation value that is used for the

dissolved oxygen mg/L measurement.

SAVE

Highlight and press enter to save displayed

data to memory.

DATA

Highlight and press enter to view and/or erase

saved data.

NAVIGATING THE SYSTEM SETUP MENU

When in the System Setup menu, the up and down arrow keys will

move the highlighted bar up and down the system setup options. See

the System Setup menu section of this manual for more information

about these options.

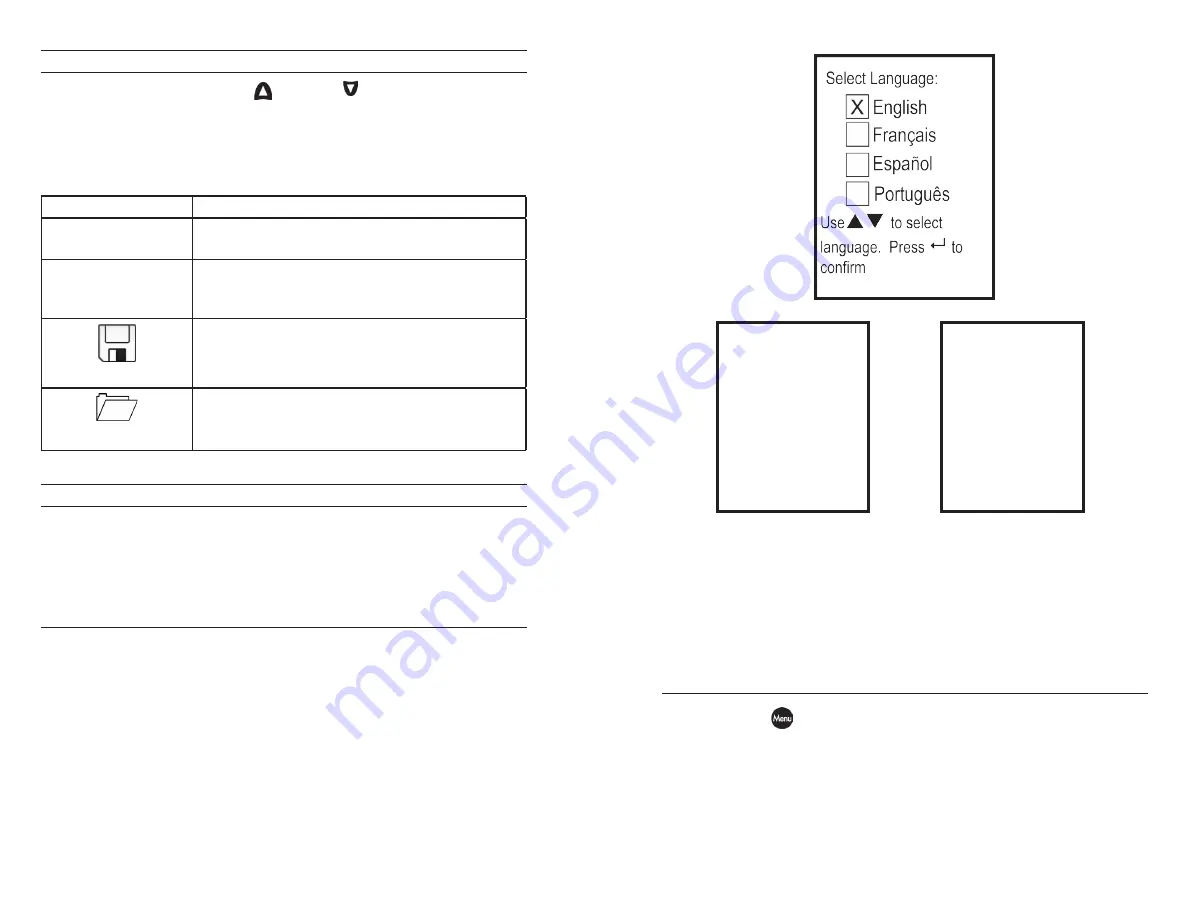

FIRST POWER ON

The instrument will step through an initial configuration when powered

on for the first time. This will set the language, dissolved oxygen sensor

type and membrane type. Use the up or down arrow keys to highlight

the appropriate language, sensor and membrane, then press enter

to confirm (figure 6). The Sensor Type must be configured for the

dissolved oxygen sensor installed on the cable. Failure to do this may

result in damage not covered under warranty. If an incorrect option is

selected, it may be changed in the System Setup menu.

Select Sensor Type:

Polaro (black)

Galvanic (grey)

Use

to select

sensor type

Press

to confirm

Select Membrane

Type:

1.25 (Yellow)

2.0 (Blue)

Use

to select

membrane

Press

to confirm

Figure 6, Select language, dissolved oxygen sensor and membrane.

After selecting a language, sensor and membrane, the Run screen will

be displayed. The next time the instrument is powered up, the Run

screen will display immediately after the splash screen. If the sensor

type or membrane type is changed, ensure that it is updated in the

System Setup menu.

S Y S T E M S E T U P M E N U

Press the menu

key to access the System Setup menu. The System

Setup menu contains three screens notated as ‘pages’. The current

page is indicated near the bottom of the display (figure 7). Use the up

and down arrow keys to scroll through menu options and menu pages.