Page

100

10.1.6 Frost Protection

Where there is a risk to the boiler or installation from frost then a suitable frost thermostat

should be fitted. Alternatively the system could be dosed with an antifreeze agent. Combination

Boiler models are fitted with frost protection as standard to protect the fabric of the boiler only.

For all other External models covered by this manual, a Frost Thermostat Kit (Code FSK2) is

available as an optional extra. This also protects the fabric of the boiler only. Details of frost

protection for the fabric of the building can be found in section 6.4 of this manual.

10.1.7 Pipework

We strongly advise that all installation pipework is run in copper. However, if plastic pipe or

plastic coated pipe is used, it must be recommended by the pipe manufacturer for use with oil

fired appliances and, in any case, the last 1000mm of pipework connected directly to the

appliance must be of copper. All connections to the appliance must be made with compression

fittings.

10.2 Sealed Systems

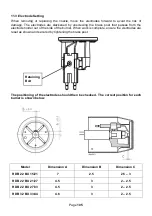

10.2.1 Expansion Vessel

Refer to Section 4.2 of this manual for standards referencing details of expansion vessel sizing.

The values given in the table below are for total system volumes which include the water

content of the boiler details of which can be found in the Technical Data Section 5.4 of this

manual. System models up to 33kW are supplied with a 12 litre expansion vessel charged to

1.0 bar. Combination Boiler models are supplied with a 24 litre expansion vessel charged to 1.0

bar. This can accommodate a maximum combined boiler and system volume of 220 litres.

Expansion vessel pre-charge pressures should be evaluated and adjusted periodically, normally

as part of servicing.

When measuring the expansion vessel bladder pre-charge pressure, using a tyre gauge, the

system should be cold and the system pressure should be relieved (by manually operating the

system pressure relief valve) in order to obtain an accurate reading.

If the maximum total system volumes stated above are to be exceeded, additional expansion

capacity will be required.

INITIAL

CHARGE

VESSEL VOLUMES

1.0

2.7

5.4

8.2

10.9

13.6

16.3

19.1

21.8

24.5

27.2

30.0

32.7

SYSTEM

VOLUME

25

50

75

100

125

150

175

200

225

250

275

300

Do not allow the flexible hoses connected to the expansion vessel to become twisted, kinked or

flattened. This may cause collapse of hose bore compromising the function of the expansion

vessel.

10.2.2 System Boiler Filling

For all System and Combination Boilers a filling point complete with a filling loop is supplied

fitted to the expansion vessel. The filling loop

MUST

be disconnected from the mains supply

after filling. A system pressure when cold of 1 bar is recommended. After filling, vent all air from

the system. The plastic plugs of the auto air vent(s) factory fitted to the boiler must be loosened

when filling the system in order to bleed the air from the boiler, then re-tightened when filling is

complete.

Содержание Agentis Series

Страница 2: ......

Страница 30: ...Page 29 4 5 Components 4 5 1 B Series Boilerhouse Casing Key Components...

Страница 31: ...Page 30 4 5 2 I Series Internal Casing 21 26 33 Models 44 Models...

Страница 32: ...Page 31 4 5 3 I Series Internal Key Components 21 26 33 Models 44 Models...

Страница 33: ...Page 32 4 5 4 I Series Internal Pump Group 21 26 33 Models 44 Models...

Страница 34: ...Page 33 4 5 5 I Series Internal System Components SK3 4 5 6 I Series Internal Combination Boiler Key Components...

Страница 35: ...Page 34 4 5 7 E Series External Casing 21 26 33 Models 44 Models...

Страница 36: ...Page 35 4 5 8 E Series External Key Components 21 26 33 Models 44 Models...

Страница 37: ...Page 36 4 5 9 E Series External Pump Group 21 26 33 Models 44 Models...

Страница 39: ...Page 38 4 5 12 Combination Boiler Pipe Layout...

Страница 41: ...Page 40 5 1 2 I Series Internal I21 I26 I33 5 1 3 I Series Internal I44...

Страница 42: ...Page 41 5 1 4 I Series Internal Combination Boilers I21C I26C I33C 5 1 5 E Series External E21 E26 E33...

Страница 43: ...Page 42 5 1 6 E Series External Base Tray E21 E26 E33 5 1 7 E Series External E44...

Страница 44: ...Page 43 5 1 8 E Series External E44 Base Tray 5 1 9 E Series External Combination Boilers E21C E26C E33C...

Страница 45: ...Page 44 5 1 10 E Series External Combination Boiler Base Tray E21C E26C E33C...

Страница 60: ...Page 59 6 3 2 Wiring Diagram Fuses The appliance must have a permanent live supply connected to operate...

Страница 61: ...Page 60 6 3 3 External 230V Two Channel Programmer Room Thermostat Optional Outdoor sensor...

Страница 62: ...Page 61 6 3 4 Internal Two Channel Programmer and Room Thermostat Optional Outdoor Sensor...

Страница 73: ...Page 72 6 6 9 Honeywell Y Plan Independent CH DHW Fully Pumped Only 2 CHANNEL TIMECLOCK...

Страница 74: ...Page 73 6 6 10 Honeywell S Plan Independent CH DHW Fully Pumped Only 2 CHANNEL TIMECLOCK...

Страница 93: ...Page 92 Kabin Pak External Plume Management Kit KPMK The kit comprises...

Страница 107: ...Page 106 11 4 Burner Start Up Cycle Lock out is indicated by a lamp on the control box...

Страница 122: ...Page 121 14 SPARES 14 1 RDB 2 2 BX Spares...

Страница 124: ...Page 123 14 2 RDB 3 2 BX Spares...

Страница 134: ...Page 133 Intentionally left blank...

Страница 135: ......