104

107774-02 - 4/18

5. Outdoor Air Reset

If an outdoor temperature sensor is connected

to the boiler and Outdoor Reset is enabled, the

Central Heat setpoint will automatically adjust

downwards as the outdoor temperature increases.

When the water temperature is properly matched

to heating needs there is minimal chance of room

air temperature overshoot. Excessive heat is not

sent to the room heating elements by “overheated”

(supply water temperature maintained too high

a setting) water. Reset control saves energy

by reducing room over heating, reducing boiler

temperature & increasing combustion efficiency

and, reducing standby losses as a boiler and

system piping cool down to ambient following

room over heating.

6. Boost Time

When the Central Heat Setpoint is decreased by

Outdoor Air Reset settings the Boost function can

be enabled to increase the setpoint in the event

that central heat demand is not satisfied for longer

than the Boost Time minutes. The Boost feature

increases the operating temperature setpoint by

10°F (5.6°C) every 20 minutes (field adjustable)

the central heat demand is not satisfied. This

process will continue until heat demand is

satisfied (indoor air is at desired temperature),

or the central heat setpoint is reached. Once the

heat demand is satisfied, the operating setpoint

reverts to the value determined by the Outdoor

Air Reset settings. If Boost Time is zero, then the

boost function is not used

.

7. Domestic Hot Water (DHW) Setpoint

Upon a DHW call for heat the setpoint is the user

entered DHW setpoint . When DHW has priority the

boiler will modulate in an attempt to maintain the

DHW set-point at the DHW sensor located near

the hot water connection. The factory default for

this setting is 120F.

8. Domestic Hot Water Priority (DHWP)

By default, when there is call for both CH and

DHW, the DHW demand takes priority for the

first 60 minutes of continuous simultaneous

demand. This means that all boiler output

will be directed to the DHW demand and the

boiler will modulate as needed to maintain

the temperature of the domestic hot water

leaving the boiler at the DHW set-point. Also

by default, during this time the system pump

will circulate water through the system even

though no heat is entering the system from the

boiler (this behavior increases the odds that a

“micro zone” demand can be satisfied using

the heat in a buffer tank or elsewhere in the

system).

At the end of the priority time, the boiler will

divert its entire output to the CH demand and

will revert to the CH set point as measured at

the supply sensor. At this point all heating of

DHW will end until there is an interruption in

either the CH or DHW demand. The default

60 minute DHW priority time can be increased

to as much as 120 minutes (see “Changing

Adjustable Parameters”).

C. Boiler Protection Features

1. Supply Water Temperature High Limit

The control is equipped with internal operating

control and high limit features. The control

monitors a dual element temperature sensor

that is mounted in the supply water manifold

and provides UL353 and UL1998 internal

safety algorithms. If supply water temperature

increases above the active setpoint plus diff

above, default 190°F (87.7°C) the boiler is cycled

off. If the temperature exceeds 210°F (98.9°C), a

manual reset hard lockout results. If the boiler is

responding to the internal Multiple Boiler Control

Sequencer, or an External EMS demand and the

supply water temperature increases above 190°F

(87.7°C) the control begins to reduce the blower

maximum speed setting and if the temperature

increases to 200°F (93°C) a forced recycle results.

Additionally, if the supply temperature rises faster

than the degrees Fahrenheit per second limit a

soft lockout is activated.

2. High Differential Temperature Limit

The Control monitors the temperature difference

between the return and supply sensors. If this

difference exceeds 52°F (29°C) the control

begins to reduce the maximum blower speed.

If temperature difference exceeds 62°F (34°C) a

forced boiler recycle results. The unit will restart

automatically once the temperature difference

has decreased and the minimum off time has

expired. If the temperature difference remains

above 72°F (40°C) for longer than 3 minutes a

manual reset hard lockout results.

3. Return Temperature Higher Than Supply

Temperature (Inversion Limit)

The Control monitors the supply and return

temperature sensors. If the return water

temperature exceeds the supply water temperature

for longer than a limit time delay the Control shuts

down the boiler and delays restart. If the inverted

temperature is detected more than five times, the

boiler manual reset Hard Lockout is set. This

condition is the result of incorrectly attaching the

supply and return piping.

XIII. Operation

(continued)

Содержание K2WTC-135

Страница 10: ...10 107774 02 4 18 Figure 4 1 Minimum Clearances To Combustible Construction IV Locating the Boiler continued...

Страница 12: ...12 107774 02 4 18 Figure 5 1 Wall Layout Mounting Hole Location V Mounting The Boiler continued...

Страница 74: ...74 107774 02 4 18 Figure 9 2 Piping Method 1 Near Boiler Piping Heating Only IX System Piping continued...

Страница 76: ...76 107774 02 4 18 Figure 9 5 Piping Method 1 Near Boiler Piping Shaded Boiler Loop IX System Piping continued...

Страница 81: ...81 107774 02 4 18 X Domestic Hot Water Piping continued Figure 10 1 Domestic Hot Water Piping...

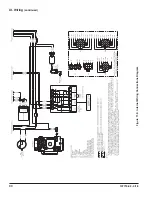

Страница 87: ...87 107774 02 4 18 Figure 11 6 J3 Field Wiring Figure 11 5 4 20 mA EMS Field Wiring XI Wiring continued...

Страница 89: ...89 107774 02 4 18 XI Wiring continued...

Страница 90: ...90 107774 02 4 18 Figure 11 8 Internal Wiring Connections Diagram XI Wiring continued...

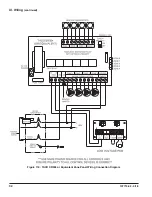

Страница 92: ...92 107774 02 4 18 Figure 11 9 TACO SR504 or Equivalent Zone Panel Wiring Connection Diagram XI Wiring continued...

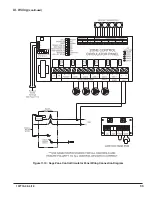

Страница 93: ...93 107774 02 4 18 Figure 11 10 Sage Zone Control Circulator Panel Wiring Connection Diagram XI Wiring continued...

Страница 101: ...101 107774 02 4 18 Lighting and Operating Instructions XII Start Up and Checkout continued...

Страница 142: ...142 107774 02 4 18 XVI Repair Parts continued...

Страница 145: ...145 107774 02 4 18 XVI Repair Parts continued...

Страница 148: ...148 107774 02 4 18 XVI Repair Parts continued...

Страница 150: ...150 107774 02 4 18 XVI Repair Parts continued...

Страница 152: ...152 107774 02 4 18 XVI Repair Parts continued 120 121 122 123 124 125 126 127...

Страница 159: ...159 107774 02 4 18 SERVICE RECORD DATE SERVICE PERFORMED...

Страница 160: ...160 107774 02 4 18 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...