115

114

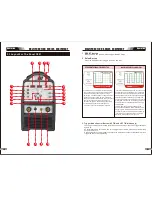

MIG

SERIES

EQUIPMENT

R221,R231,R251,R311 MIG welding machines adopts the latest pulse width modulation

(PWM) technology and insulated gate bipolar transistor (IGBT) power module, which can

change work frequency to medium frequency so as to replace the traditional hulking work

frequency transformer with the cabinet medium frequency transformer. Thus, its characterized

with portable, small size, light weight, low consumption and etc.

1.1 Brief Introduction

◆

MCU control system, responds immediately to any changes.

◆

High frequency and high voltage for arc igniting to ensure the success ratio of igniting arc.

◆

Lift TIG operation, If the tungsten electrode touches the workpiece when welding,

the current will drop to short-circuit current to protect tungsten.

◆

Simple select material/wire diameter and the stored know-how controls the welding

process automatically

Summary

1.2 Working Principle

230V

The working principle of R221/R231/R251/R311 welding machines is shown as the

following figure. Single-phase 230V work frequency AC is rectified into DC(about 312

V), then is converted to medium frequency AC (about 20-40KHz) by inverter device (IGBT

module), after reducing voltage by medium transformer (the main transformer) and

rectifying by medium frequency rectifier (fast recovery diodes),then is outputted DC .The

circuit adopts current feedback control technology to insure current output stably.

Meanwhile, the welding current parameter can be adjusted continuously and steplessly to

meet the requirements of welding craft.

◆

occoured, the alarm lamp on the front panel will be on and the output current will

be cut off. It can self-protect and prolong the using life.

Intelligent protection: over-current, over-heat, when the mentioned problems

R221, R231, R251,R311 MIG machines Characteristics:

Summary

MIG SERIES

EQUIPMENT

1.3 Specifications R221

Due to variations that can occur in manufactured products, claimed performance, voltages,

ratings, all capacities, measurements, dimensions and weights quoted are approximate

only. Achievable capacities and ratings in use and operation will depend upon correct installation,

use, applications, maintenance and service.

NOTE

Description

490X225X380mm

15.9kg

Fan Cooled

Multi Process Inverter Power Source

EN 60974-1 / IEC60974-1

1

230VAC ± 15%

50/60Hz

66V

10-25 V

2.5-18

5kg

0.6/0.8/1.0

IP23

F

Up to 0.8mm

80%

0.73

25-200 A

30-170 A

22.6 A

35.7 A

Dimensions

Weight

Cooling

Welder Type

European Standards

Number of Phases

Nominal Supply Voltage

Nominal Supply Frequency

Open Circuit Voltage

Output Voltage Range

Wirefeeder Speed Range

Wire roll weight

Wire roll diameter

Protection Class

Insulation Class

Thickness of material

Efficiency

Power Factor

Welding Current Range (MIG Mode)

Welding Current Range (STICK Mode)

Effective Input Current

Maximum Input Current

Single Phase Generator Requirement

Duty cycle, 40°C, 10 min(MIG)

R221

200A@ 40%24V 155A@ 100%20.3V

Gas Follow

3s

Duty cycle, 40°C, 10 min(MMA)

170A@ 40%26.8V 107A@ 100%24.2V

12.3KVA