75

74

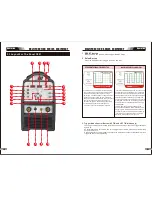

8. JOB and SAVE

9. Negative Welding Terminal

Negative Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

Anti-stick prevents the electrode from annealing.

If the electrode sticks in spite of the arcrorce device, the

machine automatically switches over to the minimum

current within about 1 second to prevent the electrode

from overheating. In order to easily separate the

electrode and electrode holder to protect the welder.

Antistick

A

nt

is

ti

ck

U

I

5. Negative Control

The Negative button is used to minus selected in Programming sequence..

Positive Control

The Positive button is used to plus selected in Programming sequence..

7. Hot Start

Arcforce Correction

Hot Start

Function reliably ignites the electrode

and melts perfectly to ensure the best quality

even at the start of the seam. this solution makes

lack of fusion and cold welds a thing of the past

and significantly reduces weld reinforcement.

Adjust the hot start current here and the time here.

During the welding process, arcforce prevents

the electrode sticking in the weld pool with

increases in current. this makes it easier to weld

large-drop melting electrode types at low current

strengths with a short arc in particular.

I

t

Operation

Operation

DC PULSE

SERIES

EQUIPMENT

DC PULSE

SERIES

EQUIPMENT

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug

being fused in the terminal.

2.2 Control Panel

10. Positive Welding Terminal

Positive Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

12. 5 Pin Control Socket

The 5 pin receptacle is used to connect a trigger switch or remote control to the welding

Power Source circuitry:

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

11. Shielding Gas Outlet

The Shielding Gas Outlet located on the front panel is a fast connection of a suitable

TIG Torch.

1

.

Gas Pre-Flow

T231: Absolute setting range 0.1s to 5s (0.1S increments)

T331: Absolute setting range 0.1s to 20s (0.1S increments)

This parameter operates in TIG modes only and is used to provide gas to the weld zone

prior to striking the arc, once the torch trigger switch has been pressed. This control is

used to dramatically reduce weld porosity at the start of a weld.

2.Initial Current

T231:

The main current Setting range 5AMP to 200AMP

This parameter operates in (4T) TIG modes only and is used to set the start current for TIG.

The Start Current remains on until the torch trigger switch is released after it has been

depressed.

Note: The maximum initial current available will be limited to the set value of the base

current.

T331:

The main current Setting range 10AMP to 300AMP

6. Digital Ammeter / Parameter meter

The digital Ammeter is used to display the actual output current of the power source. It is

also used to display Parameters in Programming Mode.

Depending on the Programming Parameter selected, the status indictor adjacent to the

Ammeter will illuminate to show the units of the programming parameter.

When welding, the Ammeter will display actual welding current.

Selecting Function Button

This button can select different programming parameter

You can press JOB to select the memory records that you have saved before from 1-9.

For the new setting of present current Amps ,just press SAVE.