107

106

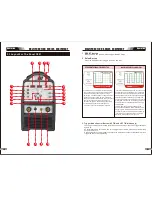

2.9 Set-up For LIFT TIG (GTAW) Welding O251

WARNING

Before any welding is to begin, be sure to wear all

appropriate and recommended safety equipment.

NOTE

Operation

Operation

The following set up is known as straight polarity or DC electrode positive. This is

commonly used for DC LIFT TIG welding on most materials such as steel and stainless

steel.

1. Switch the ON/OFF switch (located on the rear panel) to OFF.

2. Connect the work lead cable to the positive output terminal, and the LIFT TIG torch

cable to the negative output terminal.

3. Connect the gas line/hose to the proper shielding gas source.

4. Slowly open the Argon cylinder valve to the fully open position.

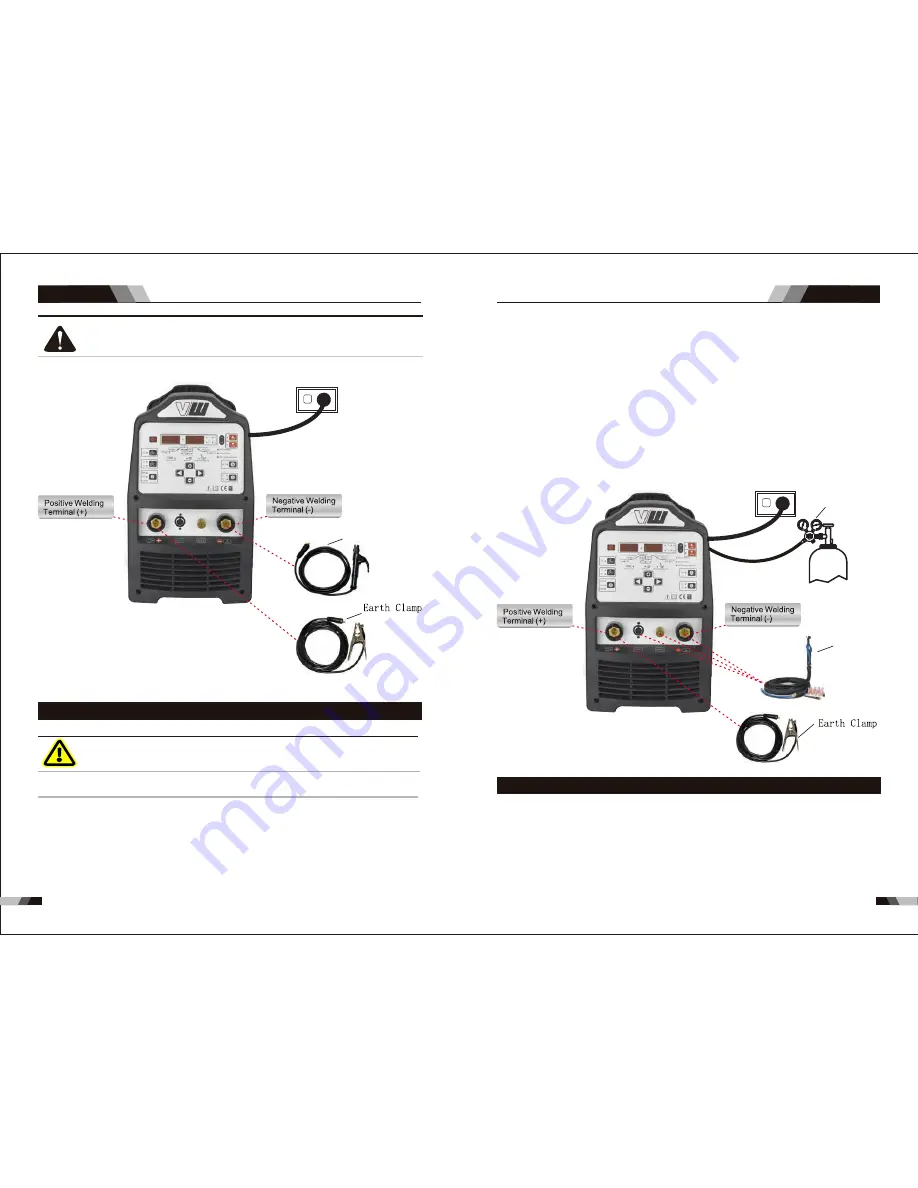

2.10

Setup For Cutting (CUT) O251

In order for the unit to function correctly, it must be installed properly. Follow the procedure

given below for correct installation:

power supply

Ar./GAS(TIG/WIG)

TIG torch

MULTIFUNCTION

SERIES

EQUIPMENT

MULTIFUNCTION

SERIES

EQUIPMENT

power supply

Electrode holdder

CAUTION

Loose welding terminal connections can cause

overheating and result in the male plug being fused

in the bayonet terminal.

1. Read the safety rules given in this manual carefully.

2. Check on receiving the unit that there are no defective parts or parts damaged during

transportation.

3. Attach air regulator as show in picture Air Regulator Installation only for O251.

5. Connect the work lead clamp to your work piece.

6. The tungsten must be ground to a blunt point (similar to a pencil) in order to achieve

optimum welding results. See illustration. It is critical to grind the tungsten electrode

in the direction the grinding wheel is turning. Grind at a 30 degree angle and never

to a sharp point.

7. Install the tungsten with approximately 1.6mm to 3.2mm sticking out from the

gas cup, ensuring you have correct sized collet.

8. Tighten the back cap.

9. Turn the switch to the “ON” position. The power L.E.D. light should illuminate.

10. Set the welding process to LIFT TIG.

11. Set the Weld Current Control Knob to the desired amperage.

12. You are now ready to begin LIFT TIG Welding.