24-hour s358 (0)40 837 1150 • Email: [email protected]

operation and programming vacon

z

50

5

1. Make the Keeper parameters visible by changing

150 (Show Clock Parameters)

to a value of

Yes.

2. Make sure that the correct date and time are displayed in

.

3. Choose which analog input channel will be used as the input signal to the Keeper. Set up the analog input

channel for the proper analog input configuration. Note that you can also set up an input from an encoder

as the input to the Keeper function.

parameter 380 (Keeper Input Cfg)

to the value that is the input signal you chose for the Keeper

function.

5. Choose the units to be used by the Keeper by changing

to the desired units.

The default is GPM; if you want that unit, you can skip this step. If the option for units is not available, you

can choose to program the engineering units of the drive as the units of the input function. Do this by

selecting User Units for the Keeper Units parameter and programming

the text you want.

6. Modify

parameter 381 (Keeper Max Scale)

to the value to be displayed with the analog input sensor is at

its maximum value. For example, if you are using a 4-20 mA sensor and it produces an output of 0-1000

GPM, then you should configure the analog input to 4-20 mA and set parameter 381 to a value of 1000.

This value should represent the maximum of your sensor.

7. Verify that the Keeper input signal is scaled correctly. Do this through

. This

parameter should be displaying the value the sensor is outputting. Make sure that this value has been

scaled correctly.

8. Configure the times that the Keeper will save data. To do this, decide whether you want the Keeper to save

data once, twice, or three times a day. Program this choice into

parameter 384 (Keeper Save Rate)

. If you

want the Keeper to save data once a day, select 24 hour. Twice a day would be 12 hour; three times a day

would be 8 hour.

9. Program the

exact time that the Keeper will save data. Do this by programming a time value

into

parameter 382 (Keeper Save Time)

. The Keeper will save the total value of the processed variable

every 8 or 12 or 24 hours, depending on your selection in Keeper Save Rate.

10. Now program the rate of the input variable using

parameter 386 (Keeper Time Rate)

. The selection

of this parameter should be made based on the units you are accumulating. For example, if you are

pumping gallons per minute (GPM), program this parameter to minute. If you are pumping liters per

second, program second. The parameter should match the time base of the units you are accumulating.

11. The Keeper is now set up and ready to collect data. The last step should be to reset the records to be

collected. Depending on the order of parameters programmed, you may have false data in your initial

records. To reset the records, navigate to

parameter 801 (Program Number)

and enter a value of 40. This

will reset the Keeper records so that valid data can be collected. The Keeper will collect data until the first

save time that you have programmed into the drive. This data will be saved in a partial data record that

you will be able to determine from the number of minutes accumulated.

12. You can extract the Keeper records from the drive with a USB flash memory device or memory stick. (See

“Storing Keeper Files” on page 47

.) When you extract the data from the drive, it will be presented to you

in a comma-separated file (.csv) that can be opened in Excel. The format of the data will be as follows:

The Date and Time represent the time the data was saved to the record. In this case, the

units of the Keeper function were configured to be GPM. The fourth column then

indicates the number of gallons pumped during the period ending at the Date and Time

indicated. If you were to configure the Keeper to units of LPS, this field would indicate

Liters. The period field indicates the number of minutes the drive was available to run

during that period. The KWHour field allows you to determine what energy was supplied

to the drive during the period.

5.9 Using the Vacon 500x Real-Time Clock and Other Special Features

parameter 150 (Show Clock Param)

to access the functionality of the Vacon 500x real-time clock,

a wide range of features is available. To do this, first change parameter 150 in Level 2 programming mode

to Yes.

5.9.1 Enabling the Vacon 500x Based on Time of Day (TOD)

The Vacon 500x includes two “enable” windows that can control when the drive is allowed to run during the

course of a work day, Monday through Friday, and an additional “enable” window for weekends. To use this

enable function, select the time in your time zone

(parameter 151, Time Zone Setup

) and the clock hour in

24-hour military time for both enable and disable times. The following table shows both weekday enable

functions

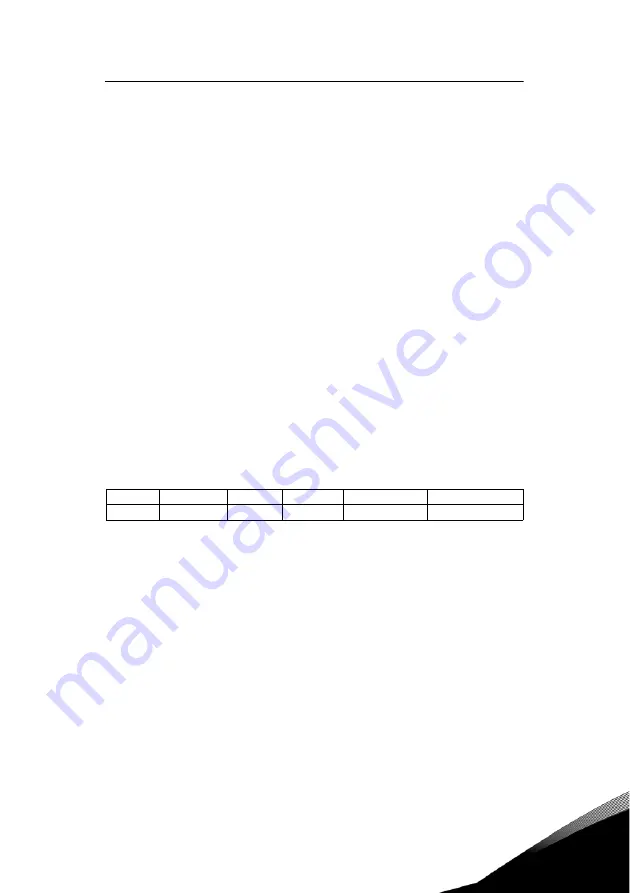

DATE

TIME

DAY

GALLONS

PERIOD(MINS)

KWHOUR

1/1/2000

0:00

Fr

10000

480

500

Содержание 500X

Страница 1: ...vacon 500x ac drives user s manual ...

Страница 9: ...24 hour support 358 0 40 837 1150 Email vacon vacon com summary of vacon 500x parameters vacon z 8 ...

Страница 13: ...24 hour support 358 0 40 837 1150 Email vacon vacon com introduction vacon z 12 1 ...

Страница 27: ...24 hour support 358 0 40 837 1150 Email vacon vacon com receiving and installation vacon z 26 3 ...

Страница 117: ...24 hour support 358 0 40 837 1150 Email vacon vacon com troubleshooting vacon z 116 8 ...

Страница 119: ...24 hour support 358 0 40 837 1150 Email vacon vacon com vacon 500x ultraflex options vacon 9 ...

Страница 121: ...24 hour support 358 0 40 837 1150 Email vacon vacon com appendix binary hexadecimal conversion vacon z 120 A ...

Страница 123: ......