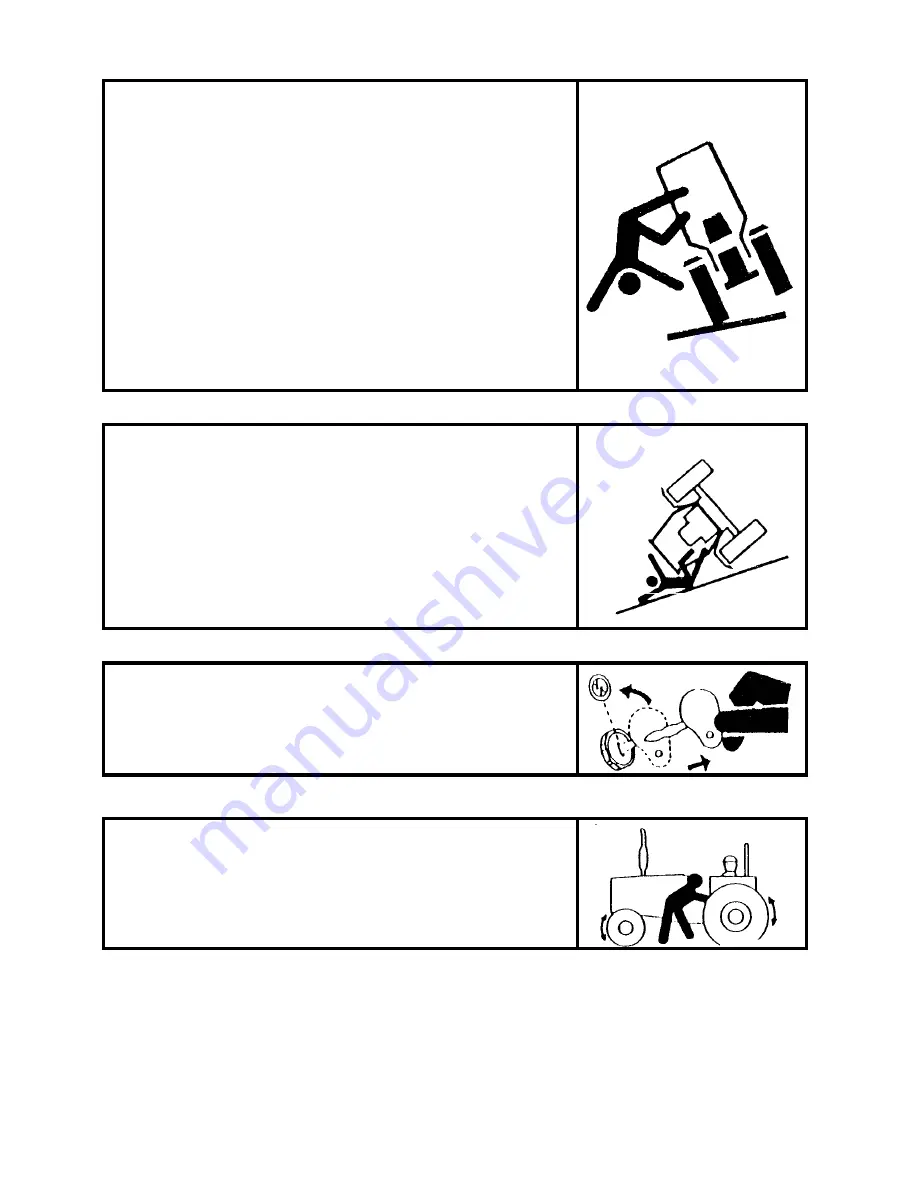

USE OF ROPS AND SEAT BELT

The Roll Over Protective Structure(ROPS) has been certified to

industry and/or government standards. Any damage or alternation

to the ROPS, mounting hard-ware, or seat belt voids the

certification and will reduce or eliminate protection for the

operator in the event of a roll-over. The ROPS, mounting

hardware, and seat belt should be checked after the first 100 hours

of Tractor and every 500 hours thereafter for any evidence of

damage, wear or cracks. In the event of damage or alteration, the

ROPS must be replaced prior to further operation of the Tractor.

The seat belt must be worn during machine operation when the

machine is equipped with a certified ROPS.

Failure to do so will reduce or eliminate protection for the

operator in the event of a roll over.

PRECAUTION TO AVOID TIPPING

Do not drive where the Tractor could slip or tip.

Stay alert for holes and rocks in the terrain, and other hidden

hazards.

Slow down before you make a sharp turn.

Driving forward out of a ditch or mired condition could cause

Tractor to tip over backward. Back out of these situations if

possible

1-6

possible

PARK TRACTOR SAFELY

Before working on the Tractor ;

Lower all equipment to the ground.

Stop the engine and remove the key

KEEP RIDERS OFF TRACTOR

Do not allow riders on the Tractor.

Riders on Tractor are subject to injury such as being stuck by

foreign objects and being thrown off of the Tractor

Содержание T233 HST

Страница 14: ...1 11...

Страница 15: ...1 12...

Страница 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Страница 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Страница 60: ...3 HST main pump case 4 5...

Страница 64: ...6 Hydrostatic system schematic 4 8...

Страница 100: ...3 Rear transmission case 5 15 Fig 5 23...

Страница 121: ...Power Train Diagram Fig 5 60 5 36...

Страница 210: ...SECTION 6 WIRING DIAGRAM 10 12...