3.3 REASSEMBLY

Reassemble the parts in reverse order of

disassembly, following these instructions.

1) Apply an adhesive (THREE BOND TB1215)

to the following parts.

a.Contact surfaces between the final case B

and wheel shaft cover.

b.Contact surfaces between the final case A

and front axle.

2) The installed wheel shaft should turn smoothly.

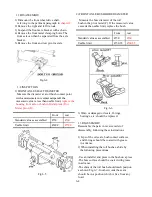

3) When installing unitized seals on the wheel

shaft cover and the rotating part between the

final cases (A and B), apply force only to the

outer circumference of the seal as shown in

Fig.6-26 to avoid deformation.

Apply force only to the shaded parts

Take care not to deform these portions

-

Wheel shaft cover

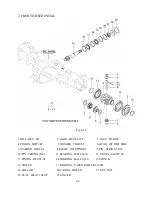

1) Every snap ring(13) should be seated securely

in its groove.

2) Be sure the numbers of Bevel gear is correct

(teeth numbers are

44T

)

Fig.6-27

-Final drive case A

1) Each parts should be washed clean before

reassembly.

2) Apply multi-purpose, quality grease to

bearings in advance

3) Every time a gear and bearings are installed,

its smooth rotation should be checked

5) Apply oil to the housing ahead of time to

6-13

Fig.6-26

4) The oil seal should be coated with grease in

advance. Then install them carefully, assuring

that their lips are not turned over.

5) The reassembled final case (B) should turn

smoothly until it makes contact the stopper.

6) When the wheel(tire) is reinstalled, turn it by

hand to make sure that all the mechanism

turns smoothly without making any noise.

7) After adjustment of the toe-in, perform road

tests. There should be no abnormalities such

as vibration, abnormal noises, defected

steering wheel operation, etc.

5) Apply oil to the housing ahead of time to

install the mechanical seal.

6) Be sure that the length of shaft

⑧

is 145 mm.

7) Tighten the bolts to the specified torque.

Tightening torque

2.3-3.0Kgf.m

8) Adjust backlash between gear bevel 44T

⑫

and

gear bevel 8T

⑨

with collar(2mm)

⑩

Back lash

mm(in)

0.1-0.2

(0.004-0.008 in)

9) Apply an adhesive to the Cap (55), and be sure

not to deform when installing.

Note: Refer to Fig.6-23

Содержание T233 HST

Страница 14: ...1 11...

Страница 15: ...1 12...

Страница 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Страница 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Страница 60: ...3 HST main pump case 4 5...

Страница 64: ...6 Hydrostatic system schematic 4 8...

Страница 100: ...3 Rear transmission case 5 15 Fig 5 23...

Страница 121: ...Power Train Diagram Fig 5 60 5 36...

Страница 210: ...SECTION 6 WIRING DIAGRAM 10 12...