EN

35

E

N

37878

05-2017

4

.

M

ai

n

te

n

an

ce

a

n

d

c

le

an

in

g

4.4

Maintenance: annual

ã

Terberg Machines B.V., IJsselstein, The Netherlands

All rights reserved. No part of this book may be reproduced, stored in database or retrieval system, or published, in any form or in any way,

electronically, mechanically, by print, photoprint, microfilm or any other means without prior written permission from the publisher.

First carry out the

weekly and 6-weekly maintenance

• Attachment points

Tighten all the bin lift's attachment points, such as:

-

Mounting bolts of the bin lift system to the

refuse collection vehicle or adaptation frame

(assembly frame).

The tightening torque is 200 Nm.

-

Bin lift footboards (if applicable).

-

Check all bolt and nut connections.

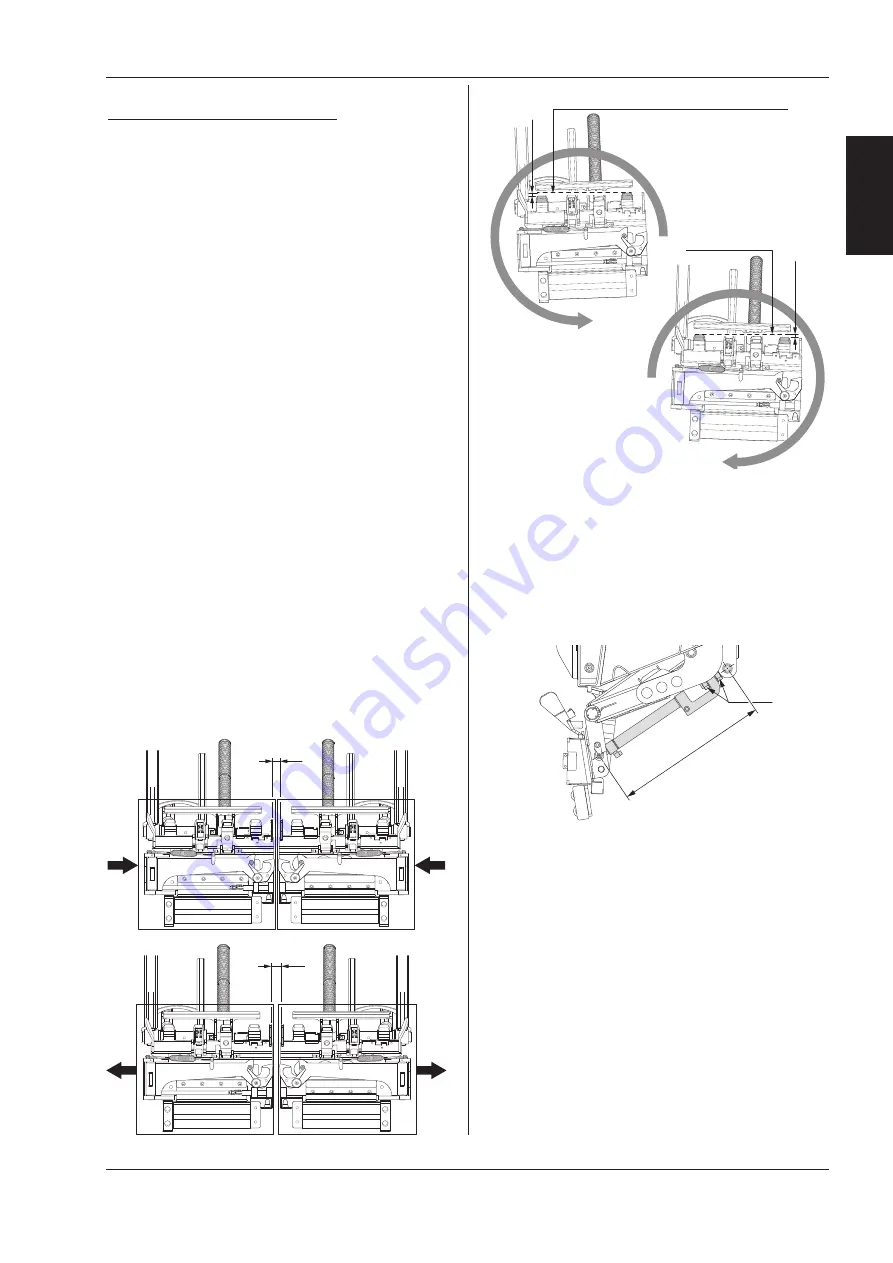

• Check the pick-up teeth for wear.

• Bearing play

Check the bin lift for excessive bearing play.

-

Press the two lifting chairs axially towards each

other and measure the opening (see fig. 4.4a).

Then pull the lifting chairs axially apart and

measure the opening again.

The difference between these two measurements

may be no more than

10 mm

.

-

Grip the lifting chair with two hands and try to

turn it vertically to the left (see fig. 4.4b) and

determine distance

X1

. Then rotate the chair

to the right and determine distance

X2

.

The sum of these two measurements may be no

more than

5 mm

.

Do the same with the other lifting chair.

• Pick-up comb tipping angle

The tipping angle has been set ex-factory. If the

pick-up combs do not make the same angle

when in the highest position, this can be

corrected by means of nuts

A

(see fig. 4.4c).

-

The nominal distance between the axles,

centre to centre, must be 730 mm.

• Cycle time

Check the bin lift cycle time.

The cycle time is calculated without the tipping

position time (dwell time) and depends on the body

height, bin/container weight and oil temperature.

-

For the measurements, use a 240 litre or a

1100 litre container. Start the measurement

when the wheels leave the ground and stop

the measurement when the wheels touch the

ground again. The tipping position time must

be subtracted from the measurement.

-

The cycle time may be no shorter than:

5 seconds for 2-wheel bins,

10 seconds for 4-wheel containers.

730

mm

A

Fig. 4.4a

X2

X1

Fig. 4.4c

Fig. 4.4b

X1

X2

Horizontal reference to right hand tooth.

Horizontal reference to

left hand tooth.