162

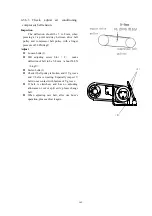

4.5.3.4 Check track tension

Run engine at low idling, move the machine

forward a distance equals to the length of

track on ground. Then stop the machine.

As shown in right fig, choose a straight long

rod; place it on track over idler (1) and carrier

roller (2), measure the max distance “A”

between upper surface of track and bottom

surface of the rod.

Standard deflection “A” should be 20-28 mm

(0.8-1.1 in).

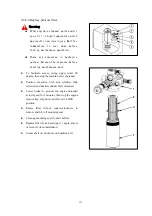

If the track tension is not at standard value,

adjust it in the following manner:

1)

Pump in grease through grease fitting(2)

with a grease pump.(pump fitting (2) and

plug screw (1) are integral)

2)

To check track to evaluate the proper

tension of track. Gradually move machine

forward

(

7-8 m

(

23 ft - 26 ft 3 in

)

.

3)

Recheck track tension, if the tension is

improper, re-adjust it.

Warning

There is a hazard that plug screw may

fly out under high lubrication grease

pressure. Never loosen plug (1) by

over one turn. (1).

Do not loosen any parts other than

plug screw (1). Do not attempt

installation facing plug screw (1).

Содержание SWE150F

Страница 19: ...12 18 No unauthorized access label Warning Stay clear of operation area of working device...

Страница 22: ...15 23 Gravity label 24 Hydraulic oil label 25 Greasing...

Страница 151: ...144 4 4 9 Hose...

Страница 193: ...186 5 Technical specification...

Страница 197: ...190 5 1 4 Circuit diagram...

Страница 199: ...192 5 1 6 Hydraulic diagram...

Страница 204: ...197 5 2 4 SWE210F Circuit diagram...

Страница 206: ...199 5 2 6 Hydraulic diagram...