8. Daily Inspection and Maintenance

70

71

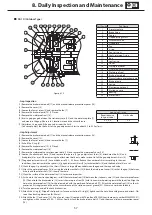

■

FB-250, ESB-250-2

(1) In the case of outdoor types, remove the outdoor cover [25]. Remove the cover [8], fan [7] and brake cover [22] (Outdoor Type).

(2) Insert M12×65 hexagon socket head bolts (prepared by customer) through the manual releasing holes, to the field. (Note that if the

hexagon socket head bolts are too long, they will hit the outer disc and deform it.)

(3) There are two manual release holes at opposing angles. By using a hexagonal wrench, tighten the bolts equally in turn in turn.

(4) To release the brake, tighten the bolts until the armature and field stick together.

(5) After returning the brake to its original state, attach the brake cover [22] (outdoor type), fan [7], and cover [8].

At this time coat the fan set screw [10] with Three Bond TB2365.

In the case of outdoor types, attach the outdoor cover as it was before.

Manual

release

hole

Manual

release

hole

Inner disc

Outer disc

Armature

Field

Hexagon

socket

head bolt

Gap

Adhesion

Hexagonal

wrench

Figure 8-37

Figure 8-38

Figure 8-39

■

One-Touch Release Lever Type

(Excluding FB-20, FB-30. FB-05A1 is optional)

All you need to do to release the brake is push the release lever over. (See Figure 8-40)

(1) To release the brake, pull the release lever out of the holder, and push it toward the load or anti-load side.

(Some specifications do not allow pushing the release lever toward the load side.)

Be careful not to push the lever too far. Pushing the lever too far could damage the brake.

(Push the release lever while checking to see if the brake is released.)

(2) When operating the motor, make certain to return the lever to its original position and set it inside the holder. Start operation after

confirming that the brake operates properly.

Note: While the lever is held down, the brake remains released. When the lever is released, the brake is applied.

Figure 8-40

When Brake is Manually Released

Premium-Efficiency Motor

Other than Premium-Efficiency Motor

When Operating