Common

7. Operation

38

39

DANGER

- Do not approach or touch rotating parts (output shaft, etc.) during operation; otherwise loose clothing may became caught

in these rotating parts and cause serious injury or death.

- When the power supply is interrupted, be sure to turn off the power switch. Unexpected resumption of power may cause

electric shock, personal injury, or damage to the equipment.

- Do not operate the unit with the terminal box Cover removed. Return the terminal box Cover to the original position after

maintenance, otherwise, electric shock may result.

- Do not operate the machine while the brake is released by the manual brake release bolt; otherwise, falling, going out of

control, or damage to the equipment may result.

CAUTION

- Do not put fingers or foreign objects into the opening of the product; otherwise, electric shock, injury, fire, or damage to the

equipment may result.

- The gearmotor or reducer becomes very hot during operation. Be careful not to touch with hands or body. Otherwise, burns

may result.

- Do not loosen the oil filler plug while the the gearmotor or speed reducer is operating. Otherwise, hot oil may fly out, result-

ing a burn.

- If any abnormality occurs during operation, stop operation immediately; otherwise, electric shock, personal injury, or fire may

result.

- Do not operate the unit in excess of the load rating; otherwise, personal injury, or damage to the equipment may result.

7-1 Items to Check Before Operation

- Oil is removed from oil lubrication parts before shipment from our factory. Supply recommended oil before use. (See P41 - 43)

- Grease is filled before shipment from the factory.

After installation and wiring are completed, check the following items before operating.

- is the wiring correct?

- is the unit properly coupled with the driven machine?

- are Mounting bolts tightened firmly?

- is the direction of rotation as required?

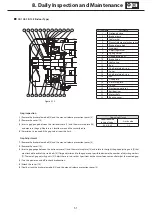

- In the case of the oil lubricating part, is the oil level at the center of the oil gauge (Fig. 7-1)

when the gearmotor or reducer is stopped?

Upon completing the above checks, run in the motor under no load, and gradually apply

a load to it. At this time, check the items in Table 7-1.

Notes: 1. Even if you align the oil level with the center of the oil gauge, the oil level may sometimes fall when the gearmotor or reducer is

stopped, due to air leakage from the inside while it is running. For this reason, be sure to check the oil level after a test run. If the oil

level is too low, replenish the lubricating oil.

2.

Before checking the oil level, wait for a while after stopping the gearmotor or reducer. You cannot check the oil level either during

operation or immediately after the end of operation.

Center of oil gauge

Figure 7-1 Oil Gauge