42

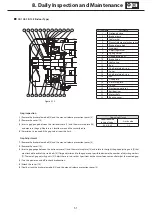

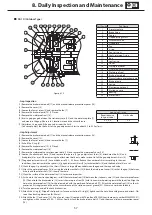

8. Daily Inspection and Maintenance

Common

43

- Ensure that the gearmotor or reducer is stopped before feeding oil to it.

- If the viscosity of the oil is high, it may take time for the oil level to become uniform. Take care not to add an excessive quantity of oil.

- Add oil until it reaches the center of the oil gauge.

- Before checking the oil level, wait for a while after stopping the gearmotor or reducer. You cannot check the oil level either during

operation or immediately after the end of operation.

- For the daily control method of oil level, see Table 8-1 on P40.

(5) Long-Period Stoppage

Table 8-6 Long-Period Stoppage

Period of

stoppage

About one

month

Replace the old oil with new one, then operate the gearmotor or reducer for several minutes, and stop

it.

One month or

more

Perform flushing, then add rust preventive oil, run the gearmotor or reducer in a no-load condition for

several minutes, and stop it.

When re-starting the gearmotor or reducer after a long-period stoppage, be sure to replace the oil with fresh one. This is because the

previously used oil may have deteriorated.

8-4 Grease Lubrication (Input Part: CYCLO Reducer)

As the gearmotor and reducer is filled with long-life grease, you can use it for a long period without replenishing the grease.

8-5

Main Unit Maintenance

- Although it will depend on operation conditions, maintenance with disassembly after approximately 20,000 hours or 3 to 5 years will

extend product lifetime.

Contact the nearest authorized maintenance shop regarding maintenance with disassembly.

- Oil seals have a lifetime. During long use natural degradation and frictional wear will reduce effectiveness. Reducer operating conditions

and ambient environment will cause lifetime to widely vary. Given normal operation, (uniform load, running 10 hours per day, normal

temperature) as a guideline it is recommended to change them every 1 to 3 years. If the sliding surfaces of oil seals or V-rings show signs

of wear or corrosion, replace them with new ones. The sliding surface of an oil seal is made of carbon steel, so in order to prevent rust

forming on it, if there are parts of the oil seal that are exposed to the outside, periodically take steps to prevent rusting by coating the oil

seal with rust preventive oil. About replacing oil seal and V-ring, please consult with nearest authorized maintenance shop.

- If stop and start are frequent, mounting bolts (or nuts) may come loose. Periodically check for looseness as this is a source of miss-

alignment, oil leakages, and load unbalance.

8-6 Motor Bearing Maintenance

- The Sumitomo standard motor is a sealed type bearing (not constructed for filling or draining grease) is used.

- When using other manufacturer’s motor due to motor’s specification, follow the operation manual for that motor.

- Although it will depend on operation conditions, maintenance with disassembly after approximately 20,000 hours or 3 to 5 years will

further increase lifetime.

- Contact the nearest authorized maintenance shop regarding maintenance with disassembly.