8. Daily Inspection and Maintenance

68

69

8-10 Changing the Brake Lining and Inner Disc

If the following conditions occur, ask the nearest authorized maintenance shop to exchange the brake linings and inner discs with

new ones.

(1) FB Brakes (excluding FB-05A1), ESB-250, ESB-250-2

When the thickness of brake lining (FB brake) or inner disc (ESB-250, ESB-250-2) reaches the use limit thickness in Table 8-8

(2) FB-05A1

When the brake gap still reaches the limit after the gap adjustment (see P45 and P56)

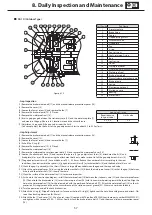

Table 8-8 Brake Lining, Inner Disc Dimensions

Brake Type

Brake Lining

Inner Disc

Dimension Drawing

Original Thickness

Usable Thickness Limit

T

0

(mm)

T

1

(mm)

T

0

(mm)

T

1

(mm)

FB-05A1

7.0

−

−

−

FB-1D

6.0

FB-1E

8.8

7.8

FB-1HE

FB-2E

9.0

8.0

FB-3E

FB-4E

10.4

8.4

FB-5E

FB-8E

10

6.0

FB-10E

FB-15E

11

7.0

FB-20

FB-30

16

12

ESB-250

ESB-250-2

6.0

1.5

3.6

0.3

- Brake torque may not be at the prescribed level during initial operation. In such a case turn the brake on and off under as light load as

possible to contact the brake’s friction surfaces.

- When changing the brake lining, replace the boss and leaf springs (for FB-5E – FB-15E, FB-20, FB-30, the gap adjusting nuts are in-

cluded) as a set.

- After 2 million or more cycles of operation, (for FB-30, ESB-250 and ESB-250-2 1 million cycles or more), or after 10 years or more have

passed since shipment from the factory, inspect to check whether continued operation is possible, even if the lining is not at the us-

able thickness limit.

- Check the following items concerning the condition of each mechanical part.

Are the linings split or chipped?

Is there any peeling or gap between the lining and the disc?

Does the brake lining or the spline of the inner disc exhibit cracking, chipping, or stepped wear?

Is there any stepped wear on the surfaces around the stud bolts or armature plate?

- Change the brake lining, even if it has not reached the usable thickness limit, in following cases. (1) if 10 or more years have elapsed

since the manufacturing date, (2) the brake is used outdoors or in a high-humidity environment, (3) if it is stored or rested for a long

period of time.

8-11 Changing the V-Ring and Waterproof Seal (Outdoor Type)

V-rings and waterproof seals degrade over the years, losing their waterproofing abilities. As a guideline contact the nearest authorized

maintenance shop every 3 years. If the sliding surfaces of oil seals or V-rings show signs of wear or corrosion, replace them with new

ones. Sliding surfaces are made of carbon steel, so rain water, condensation and other factors could cause rust to form and spread.

Because this could lead to oil seal damage, take on-going rust prevention measures.

t

0

t

1

t

1

t

0

t

0

t

0

t

1

t

1

t

0

t

0

t

0

t

1

t

1

t

0

t

0