8. Daily Inspection and Maintenance

60

61

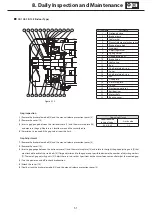

■

FB-3E, FB-4E (Outdoor Type)

Part Number

Part Name

1

Stationary core

2

Brake release

3

Manual release protection spacer

4

Brake release bolt

5

Spacer

6

Gap adjusting shims

7

Attachment bolt

8

Brake lining

9

Leaf spring

10

Boss

11

Shaft-retaining C-ring

12

Cover

13

Shaft-retaining C-ring

14

Fan

15

Fixed plate

16

Armature plate

17

Spring

18

Electromagnetic coil

19

Ball bearings

20

Motor shaft

21

Waterproof seal

22

V-ring

23

Waterproof cover attachment bolts

24

Waterproof cover

25

Shock absorber

1

2

3

4

5

6

7

8

9

10

11

G

12 13 14 15 16 17 18 19 20

21

22

23

24

X

X部詳細

25

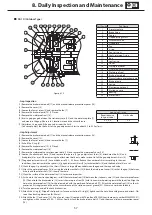

- Gap Inspection

(1) Remove the brake release bolt [4] and the manual release prevention spacer [5].

(2) Remove the cover [12].

(3) Remove the shaft-retaining C-ring [13] and the fan [14].

(4) Remove the brake release [2] (2 locations) and remove the waterproof seal [21].

(5) Insert a gap gauge between the stationary core [1] and the armature plate [16]

and measure the gap. Measure in 3 locations around the circumference.

(6) Adjustment is required if the gap value is near the limit.

(You cannot adjust the thickness of the gap adjustment shims to about 0.45 to 0.55 or less.)

- Gap Adjustment

(1) Remove the brake release bolt [4] and the manual release prevention spacer [5].

(2) Remove the cover [12].

(3) Remove the shaft-retaining C-ring [13] and the fan [14].

(4) Pull off the V-ring [22].

(5) Remove the brake release [2] (2 locations) and remove the waterproof seal [21].

(6) Remove the waterproof cover attachment bolts [23], and remove the waterproof cover [24].

(7) Loosen the attachment bolts [7] and remove the spacers [5], gap adjustment shims [6], attachment bolts [7] and fixed plate [15] as

a set. When removing the attachment bolts [7] only, make sure not to fall the gap adjustment shims [6] and the shock absorber [25].

(8) The gap adjustment shims [6] have a thickness of 0.45 – 0.55 mm. Reduce the number of shims according to the wear conditions,

then reassemble the spacers [5], gap adjustment shims [6], attachment bolts [7] and the fixed plate [15] as a set.

(9) Check the gap G, and readjust the shims if there is a large difference between the gap and the required value.

(10) Attach the waterproof cover [24] using the attachment bolts [23]. At this time align the cutout area on the side of

the waterproof cover [24] with the brake release bolt [4]. Attach the waterproof cover [24] so that the gap (A) be-

tween its hole and the motor shaft [20] is nearly the same.

(11) Clean the surface of the waterproof seal [21] to remove impurities.

(12) As shown in the construction diagram, install the waterproof seal [21] between the stationary core [1] and the

waterproof cover [24]. Then attach the brake release [2]. At this time align the hole in the waterproof seal [21] for

the release bolt with the position of release bolt [4]. Attach the waterproof seal [21] so that its protrusion fits snugly

around the entire circumference of the stationary core’s groove [1]. (Be careful that the waterproof seal [21] does

not meander. Otherwise water could leak in.)

(13) Turn the power on and off to check brake action.

(14) Attach the V-ring [22]. Wipe off the lip and surface near the lip of the V-ring [22], lightly coat the lip surface with grease, and attach.

Observe the attaching dimension (B = 6mm).

(15) Attach the fan [14], shaft-retaining C-ring [13] and cover [12].

(16) Finally, attach the brake release bolt [4] and the manual release prevention spacer [3].

Gap Value G (mm)

Required value

(original value)

Limit value

0.25 - 0.35

0.85

B

A

Figure 8-22

Details for X