SIME Brakes

13/05/16

M10054-02-A

Installation and maintenance

SIDEOS Box 2

7/17

Non contractual photographs.

Instructions of this manual must be adhered to, to obtain the performance and the safety of operation of the equipment.

Encoder and limit switch 51 questionnaire

No. Q01390-01

Dimensions limit switch 51

No. T10003-01

Installation and maintenance SIDEOS One

No. M10054-01

Limit switch 51 - Stromag

Catalog

No. D142

Installation and maintenance No. 151-00004

EMC

No. 900-00001

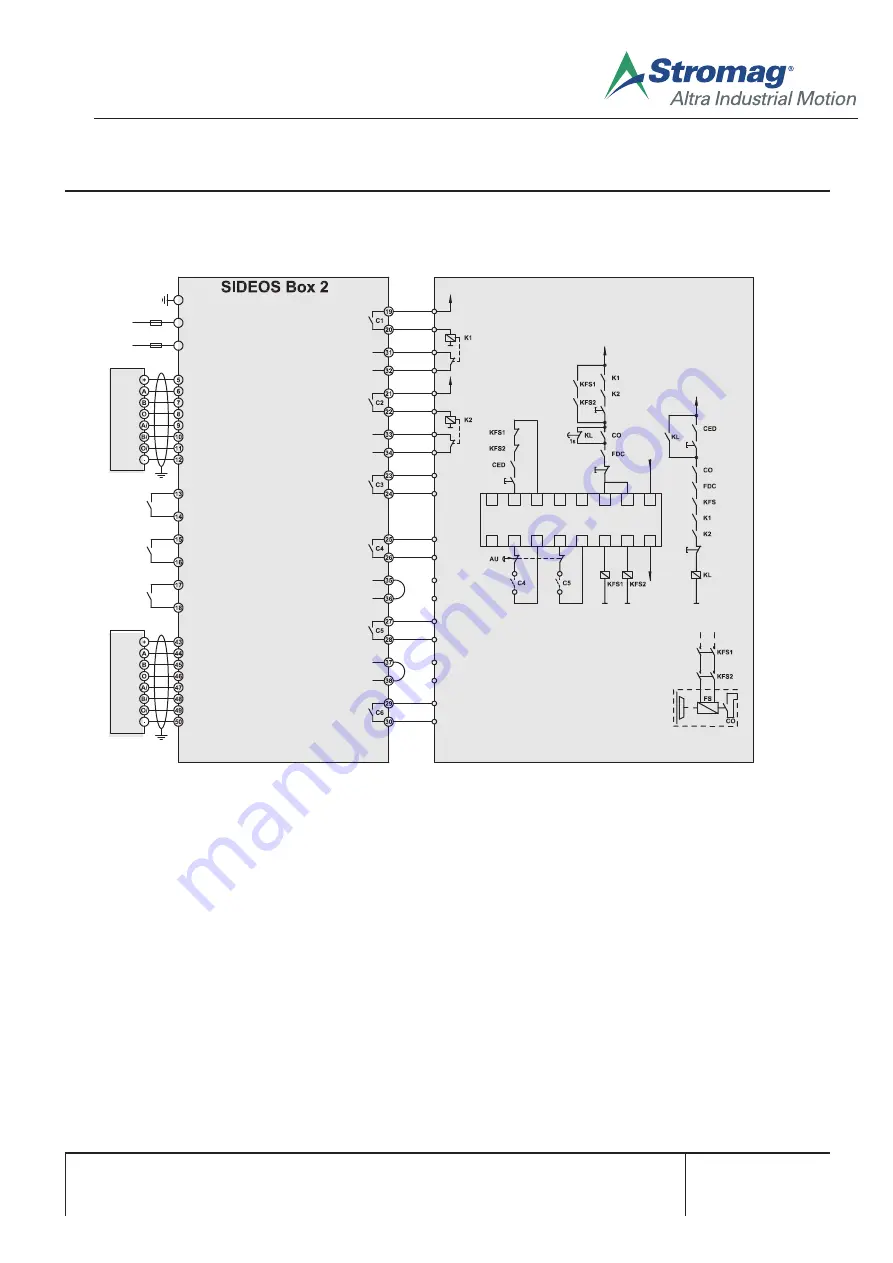

4-2 OVERSPEED (mechanical stop ) via safety relay and SYSTEM FAULT (electrical stop)

WIRING DIAGRAM

K1 and K2 relays, and KFS1 and KFS2 contactors have force-

guided contacts according to IEC 609947-5-1 standard. (NO

and NC contacts cannot close in the same time).

OVERSPEED

:

>

Overspeed / secured contacts outputs (C4 and C5) are in-

serted in the input loops of a safety relay, the contactors

KFS1 and KFS2 are inserted on the feed line of the emer-

gency brakes (Mechanical stop of type 0).

>

The loops feedbacks are inactive (terminals 35-36 and 37-

38 linked), the safety relay checking the input loops and

monitoring the contactors KFS1 and KFS2.

SYSTEM FAULT

:

>

Secured contacts outputs of System Fault (C1 and C2) drive

directly two redundant relays (K1 and K2) of the customer

PLC, they are inserted on the hoisting control line and drive

the hoisting electrical stop.

>

A NC contact of K1 and K2 relays is inserted in the respec-

tive feedback loop to check that the System Fault is taken

into account by the customer PLC.

>

If a feedback loop remains open during a System Fault trig-

gering,

SIDEOS Box 2

unit triggers a mechanical stop by

switching off the contactors K3 and K4. Restart is no allowed

before the installation reconditioning.

CATEGORY AND PERFORMANCE LEVEL

>

Category 3 or4, and overall performance level obtained:

PLd or e.

>

Selection of the safety relay and its checkings will determine

the achieved performance level.

As indicated in this diagram, connection in series of the

emergency stop contacts and the contacts of the

SIDEOS

Box 2

unit will limit the category to 3 and the maximal attai-

nable level to PLd.

Supply

Output 1 System Fault

Output 2 System Fault

Output 3 System Fault

Output 1 Overspeed

High Speed

Descent

Ascent

Feedback 1 System Fault

Feedback 2 System Fault

Feedback 1 Overspeed

Output 2 Overspeed

Output 3 Overspeed

Feedback 2 Overspeed

= Inactive feedback loop

ENCODER N°2

ENCODER N°1

Customer PLC

Start-up cde

Start-up cde

Start-up cde

STOP cde

STOP cde

Safety module

SAFETY BRAKE

AU = emergency stop

CED = external condition of start-up

CO = brake opening switch

FDC = hoisting limit switch stop

K1 = contactor 1 / System Fault

K2 = contactor 2 / System Fault

K3 = contactor 1 / Overspeed

K4 = contactor 2 / Overspeed

KFS = contactor of brake control

KL = contactor of hoisting control

SIME Brakes

www.stromag.com -

Customer service / Tel. : +33(0)1 49 90 32 20 / Fax : +33(0)1 49 89 06 38