- 37 -

- 37 -

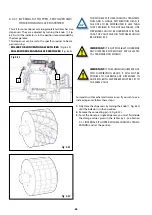

Fig. 6.50

Fig. 6.50

CALIBRATION TEST.

Dispenser

Operating speed

Rate

Calibration factor

g/turn

min.

1. Start

1ST SEED

2ND SEED OR FERTILIZER

MICRO/FERTILIZER KIT (1ST MOTOR)

MICRO/FERTILIZER KIT (2ND MOTOR)

Speed

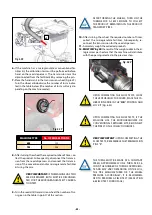

UPON COMPLETING THE FLOW TESTS, CLO-

SE THE VENTURI INJECTOR COVER, PLACE

THE CALIBRATION KNOB IN THE “

OK

”POSI-

TION AND LOCK IT (Fig. 6.51).

Fig. 6.51

Fig. 6.51

IMPORTANT:

IN DOSAGES THAT ARE CLOSE

TO TOTAL PRODUCT QUANTITIES OF 450 Kg/Ha

(TAKE INTO ACCOUNT SEED, FERTILIZER AND

MICROGRANULATE), CHECK THAT THERE IS

NO MATERIAL BUILDUP CLOGGING THE COM-

PRESSED AIR SYSTEM. IF THERE IS, REDUCE THE

DOSE.

IMPORTANT:

AFTER COMPLETING THE FIRST

HECTARE OF WORK, CHECK THAT PRODUCT

CONSUMPTION IS AT THE DESIRED LEVEL.

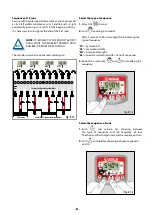

6.6 SEED DOSE FIELD TESTING

In case of differences between the test and the dose being

actually distributed by the machine due to, for instance, very

uneven or soft terrain or low-pressured wheel, etc., an ex-

perimental test can be performed to determine the

ACTUAL

AMOUNT OF ROTATIONS

in the

TRANSMISSION WHEEL

.

Fig. 6.52

1-

With a measuring tape, mark the metrical distance in the

plot as indicated in the following chart:

MACHINE TYPE

METERS TO COVER

600

41,7

700

35,7

2-

Mark the wheel for facilitating adding the amount of rota-

tions along the trajectory (Fig. 6.53).

Fig. 6.53

3-

Go over the mentioned distance with the seed driller in

operational position. In this way, the real amount of ro-

tations necessary in the previous flow test is determined.

Performing the test with this amount of rotations, the

kilograms per hectare that the machine actually distrib-

ute is determined.

IF THERE IS TOO MUCH DIFFERENCE BETWEEN

THE OBTAINED ROTATIONS IN THE FIELD TEST

AND THE AMOUNT OF ROTATIONS INDICATED

BY THE MANUFACTURED (SECTION 6.5 SEED

FLOW PRE-TESTING), MAKE SURE THAT THE

TRANSMISSION WHEEL IS ALWAYS IN CONTACT

WITH THE FLOATING WHEEL; OTHERWISE, AD-

JUST THE TENSIONER NUTS (Fig. 6.53).