- 25 -

- 25 -

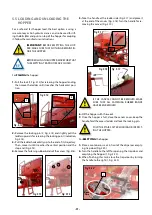

6.2.3.2 NS-PLUS MODEL

This model is fitted with two types of coulter:

FIXED COULTERS

These coulters are not height

adjustable. Consequently, the

sowing depth will be defined

by the main tines regulating

the sowing equipment’s chas-

sis (see section 6.2.1 DEPTH

TINES).

It is only possible to change the

coulters’ pressure by adjusting

the nut at bottom of the spring (1,

Fig. 6.10).

FIXED

3

1

Fig. 6.10

2

The pressure can also be adjusted by changing the bolt’s po-

sition (2, Fig. 6.10).

The coulter is fastened to the bracket by a special SOLÀ bolt

(3, Fig. 6.10) with a self-locking nut. The coulter’s side clea-

rance is adjusted using this nut.

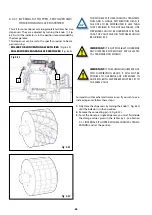

HEIGHT-ADJUSTABLE COULTERS

These coulters are aligned with the wheels of the tractor and

seed drill.

IMPORTANT:

IT IS ADVISABLE TO ADJUST THE-

SE COULTERS IF THE RUTS ARE VERY DEEP.

Adjust the spring nut to set

the pressure exerted by the

coulter on the soil (1, Fig.

6.11). The pressure can also

be adjusted by changing

the bolt’s position (2, Fig.

6.11).

These coulters are fastened

to the bracket by a special

SOLÀ bolt (3, Fig. 6.11) with

a self-locking nut. This nut

is used to set the coulter

clearance.

ADJUSTABLE

3

1

4

Fig. 6.11

2

These coulters’ depth can be adjusted individually, enabling

the coulters to be lowered to adjust their height, as follows:

1-

Adjust the nut and bolt (4, Fig. 6.18).

2-

Place the coulter in the desired position.

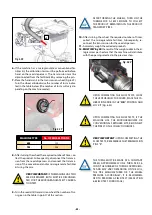

6.3 DOSAGE

Depending on the machine model, different types of dispen-

ser can be installed. The available types are the following:

• Volumetric.

• Settable roller.

Dispensers can be used with small (e.g., rapeseed) or nor-

mal-sized seeds (wheat or barley). The dispenser should be

set to the type of product and the quantity to be dispensed.

IMPORTANT:

FOR NORMAL-SIZED SEEDS, THE

TURBINE AIR REGULATOR MUST BE PLACED IN

THE N POSITION (Fig. 6.12), AND FOR DISPEN-

SING SMALL SEEDS IN VERY SMALL QUANTI-

TIES, IT SHOULD BE IN THE F POSITION (Fig.

6.13). PERFORM FIELD TESTS BEFORE STARTING

WORK. CHECK THAT THE SEED DOES NOT BLOW

OUT OF THE FURROW OR THERE IS NO MATE-

RIAL BUILDUP WHICH COULD CLOG THE COM-

PRESSED AIR SYSTEM.

Fig. 6.12

Fig. 6.12

N position

N position

Fig. 6.13

Fig. 6.13

F position

F position