- 12 -

- 12 -

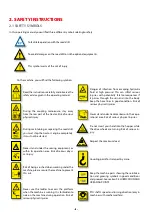

5. COMMISSIONING

The issues to take into account before starting the machine

are detailed below:

• Verify that the mechanical components are well greased.

Periodically grease the mechanical components (see sec-

tion 9.4 LUBRICATION AND GREASING POINTS).

• Verify the tyre pressure (see section 9.5 TYRE PRESSURE).

• Check that the machine’s hydraulic circuit pipes and ho-

ses and the compressed air lines (product transport) are in

good condition.

• Check the cable layout and that the connectors are firmly

coupled.

After coupling the seed driller with the tractor:

• Verify that the machine is correctly attached to the tractor.

• Before starting the machine, get familiar with all its compo-

nents and adjustments.

• Start the machine being empty in order to free the con-

ducts form any condensation of water or possible dirt.

• Adjust the machine and all its components, the type of ter-

rain and the seed.

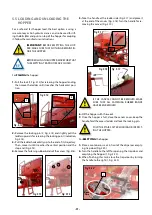

5.1

COUPLING THE SEED DRILLER TO THE

TRACTOR

The

A-6000

seed driller is fitted with a rotating shaft-ring

hook.

MAKE SURE THAT NOBODY AND NOTHING IS

BETWEEN THE TRACTOR AND THE SEED DRILL-

ER WHEN COUPLING AND UNCOUPLING.

THESE PROCEDURES REQUIRE PAYING MAXI-

MUM ATTENTION TO AVOID DAMAGE TO THE

OPERATOR.

MACHINE COUPLING AND UNCOUPLING PRO-

CEDURES MUST BE CARRIED OUT WITH THE

SUPPORT FEET AT THEIR LOWEST POSITION.

Follow the steps below for the coupling manoeuvre:

1-

Plug in the hydraulic circuit connectors of the machine

to the tractor distributor, for:

1.1

- FOLDABLE PARTS OF THE SOWING EQUIPMENT

1.2

- TRACK MARKERS

1.3

- SOWING EQUIPMENT AND TRACK ERASER

1.4

- HYDRAULIC TURBINE

1.5

- HYDRAULIC SERVICE BRAKE

THE NECESSARY HYDRAULIC CONNECTIONS

FOR THESE ELEMENTS ARE SPECIFIED IN SEC-

TION 5.3 HYDRAULIC SYSTEM.

FOR MACHINE VERSIONS WITH HYDRAULIC TUR-

BINE, PTO SHAFT MUST BE ADAPTED ONCE THE

MACHINE IS COUPLED TO THE TRACTOR (SEE

SECTION 5.2 COUPLING AND ADAPTING THE PTO

SHAFT).