- 35 -

- 35 -

5-

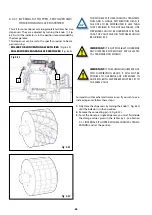

Place the supplied bag or a container underneath the

Venturi injector exit (Fig. 6.43).

Fig. 6.43

Fig. 6.43

6-

Remove the roller to identify the type and quantity of sec-

tors installed (Fig. 6.44, for removing the roller, see sec-

tion 6.3.2 ROLLER DISPENSER).

7-

Reassemble the roller in the dispenser and place the pin in

the “R” position (Fig. 6.45).

Fig. 6.44

Fig. 6.44

Fig. 6.45

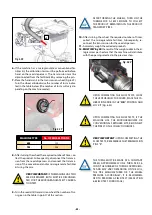

IF THE MACHINE HAS THE INTERNAL CONVEN-

TIONAL OR MICROGRANULATE FERTILIZER KIT,

BOTH PIPES OF THE MICROGRANULATE AND/

OR FERTILIZER KIT MUST BE DISCONNECTED

FROM THE COLLECTION BOXES IN ORDER TO

PERFORM THE CALIBRATION TEST (Fig. 6.46),

POINTING THE PIPE TOWARD A BAG OR CON-

TAINER.

Fig. 6.46

Fig. 6.46

x2

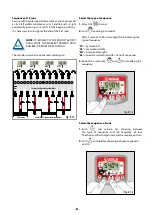

8-

To continue with the calibration, see the ISOBUS manual su-

pplied with the machine (see the section PERFORM THE CA-

LIBRATION TEST). Where you must enter the following values

(Fig. 6.47):

- OPERATING

SPEED

(Km/h).

- RATE

(dose)

(Kg/Ha),

- CALIBRATION

FACTOR

, this value can be found from:

the specific gravity of the product to be used; the type

and number of sectors mounted in the roller (see section

10.2 ROLLER DISPENSER CALIBRATION FACTOR TABLE).

Fig. 6.47

Fig. 6.47

CALIBRATION TEST.

Dispenser

Operating speed

Rate

Calibration factor

g/turn

Speed

min.

max.

1. Start