-18-

No.PF

※※

-OMX0002

■

Piping

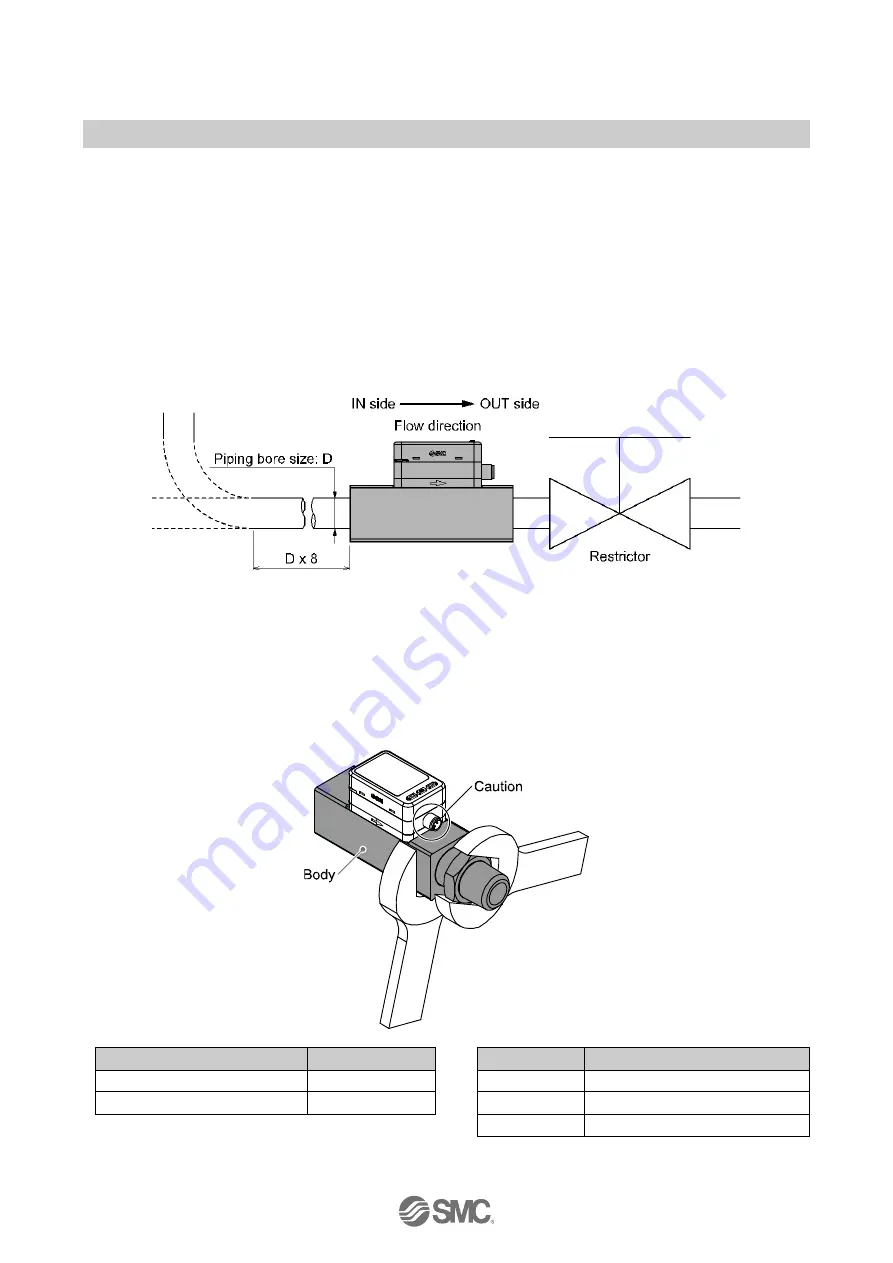

•Do not connect equipment or piping which may generate a fluctuation in flow or drift at the IN side of the

product.

When installing a regulator at the IN side of the product, make sure that hunting is not generated.

•The piping on the IN side must have a straight section of piping whose length is 8 times the piping diameter

or more.

If a straight section of piping is not installed, the accuracy will vary by approximately 3%F.S.

Refer to the graph for IN side straight pipe length and accuracy (page

).

•Avoid sudden changes to the piping size on the IN side of the product.

The accuracy may vary.

•Do not release the OUT side piping port of the product directly to the atmosphere without connecting piping.

The accuracy may vary.

•Use the correct tightening torque for piping. (Refer to the table below for the required torque values.)

•If the tightening torque is exceeded, the product can be damaged.

If the tightening torque is insufficient, the fittings may become loose.

•Avoid any sealing tape getting inside the fluid passage.

•Ensure there is no leakage after piping.

•When mounting the fitting, a spanner should be used on the body (metal part) of the fitting only.

Holding other parts of the product with a spanner may damage the product.

Specifically, make sure that the spanner does not damage the M12 connector.

Nominal thread size

Required torque

Port size

Width across flats of attachment

Rc1

、

NPT1

36 to 38 Nm

1

45 mm

Rc1 1/2, NPT1 1/2, Rc2, NPT2

48 to 50 Nm

1 1/2

60 mm

2

70 mm