20 June 2005

DRUM CHARGE

6-57

Detailed

Descriptions

6.8.2 CHARGE ROLLER VOLTAGE CORRECTION

Correction for Environmental Conditions

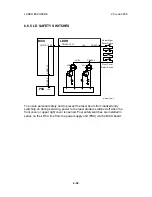

The voltage transferred from roller to drum could vary with the temperature and

humidity around the drum charge roller. The lower the temperature or humidity, the

higher the applied voltage required.

The ID sensor measures the effects of ambient conditions, and any small change

in drum potential caused by changes in temperature/humidity is reflected in the

amount of toner transferred to the drum.

This measurement is done immediately after the ID sensor pattern for toner density

control. After creating ID sensor pattern [A], another pattern [B] is made. To do this,

the LD switches off, the charge roller voltage drops, and the drum potential is

reduced to -600V. At the same time, development bias returns to -550V. The drum

potential is now slightly higher than the development bias, so only a very small

amount of toner transfers to the drum. The ID sensor measures the density of

pattern [B], and Vsdp, the output voltage, is compared with Vsg which was read

from the bare drum at the same time.

ID Sensor Pattern

t

Drum Potential

Development Bias

ID Sensor Output

-850 V

-600 V

-550 V

-480 V

-150 V

V sg (4.00 V)

V sdp (3.50 V)

V sp (0.31 V)

Charge Voltage

Laser Diode

3

cm

3 cm 3 cm

On

Off

-1500 V

Sub Scan Direction

B195D506.WMF

Содержание A-C4

Страница 1: ...Model A C4 Machine Code B195 B198 B264 B265 SERVICE MANUAL 20 June 2005 Subject to change...

Страница 112: ...LEFT COVER 20 June 2005 3 8 3 8 LEFT COVER 1 Left upper cover A x4 2 Controller cover B x2 B195R955 WMF A B...

Страница 194: ...PRINTED CIRCUIT BOARDS 20 June 2005 3 90 3 19 5 PSU 1 Left cover 3 8 2 PSU A x4 x all B195R824 WMF A...