Beijing RichAuto S&T Co., Ltd.

18

Setting mode

:

Enter “

Pulse Equiv

”, cursor is in the X axis pulse equivalent position,

press“

” to move cursor as required. Press“

” then, input a new value, and press

“

” to save. To modify X, Y and Z axis value one by one in the same way. Save all changes

and return to the "

Pulse Equivalent

" menu.

Table size

RichAuto system makes the table size as the soft limit values, in order to prevent machine over

travel. Machine size must be less than or equal to the actual size of machine table.

Setting

:

Enter “Table Size”, press “

”to move cursor as required. Press “

” and

input the new value, press “

” to save the changes. To modify X, Y and Z axis value one by

one in the same way. Save all changes and go back to the "Table size" menu.

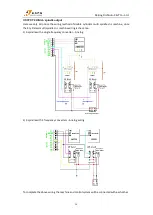

Spindle Setup

Spindle delay

:

Including start delay and stop delay(

Unit

:

ms)

.

Spindle state

:

To be used to set multi-speed control or simply spindle on/off signal control

parameters. System defaults “3-line8-state”, if user needs “1-line2-state (On/Off)”, just change

the number of lines to 1; See detailed settings at

OUTPUT SIGNAL spindle output wiring.

Home Setup

Home speed

:

The movement speed of each axis when go mechanical origin (ZERO), the system

default X, Y axis home speed: 3000 mm/minute, Z axis home speed: 1800 mm/minute.

Home order

:

Motion sequence of each axis when executing return ZERO (return mechanical

origin).

Including

:

Z,X and Y

Z,X,Y

Z,Y,X

Z only

X and Y,Z

X,Y,Z

Y,X,Z

XY zero

X zero then Y zero

Y,X

zero

None

X zero only

XZ and Y

Home direction

:

Movement direction of each axis when return ZERO. The directions are depend