16

EN

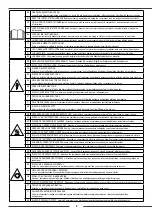

All three-phase compressors are equipped with a 16A / 32A phase-

reversing plug. After connection to the mains, the direction of rotation

must be observed.

HP kW Power supply volt/ph Plug model

2 – 3 – 4 1.5 – 2.2 – 3 220/380/3

230/400/3 16A 3 pole + ground

5.5 – 7.5 – 10 4 – 5.5 – 7.5 220/380/3

230/400/3 32A 3 pole + ground

NOTE:

The equipment must be connected to a maximum impedance

of 0.37 Ω.

NOTE:

Compressors installed on the 500 lt tank, with capacity

of HP7.5/5.5 kW and HP10/7.5 kW can be supplied a star/triangle

starting control unit.

Installation instructions:

– Secure the control unit box on a wall or on a fixed support, and

provide it with a power cable with plug, of a diameter in proportion to

its length.

– Any damage caused by incorrect connections of the power line

to the mains, automatically excludes warranty of electrical parts.

To avoid connection errors, we advise you to contact a specialised

technician.

IMPORTANT:

Never use the ground socket instead of the neutral wire. The ground

connection must be made to meet safety standards (EN 60204). The

plug of the power cable must not be used as a switch, but must be

fitted in a power socket controlled by a suitable differential switch

(thermal-breaker).

STARTING

Check that the mains power matches that indicated on the electrical

data-plate (fig.14) the permissible tolerance range is +/-5%. When

first starting compressors operating on 3-phase voltage, check the

rotation direction of the cooling fan by comparing it with the direction

of the arrow on the belt guard or on the protective housing. Turn or

press into position “0” (according to the type of pressure switch fitted

on the appliance) the knob located on the upper section (fig. 15). Fit

the plug in the power socket (fig. 12 - 13) and start the compressor,

turning the pressure switch knob into position “I”. The compressor

is fully automatic, and is controlled by the pressure switch which

stops it when tank pressure reaches maximum value and restarts

it when it falls to minimum value. The pressure difference between

maximum and minimum values is usually about 2 bar (29 psi). E.g.:

the compressor stops when it reaches 8 bar (116 psi – maximum

operating pressure) and restarts automatically when the pressure

inside the tank drops to 6 bar (87 psi). After connecting the compressor

to the power line, load it to maximum pressure and check exactly how

the machine is operating.

When the temperature is <10 ° C it is recommended to make the

first start with the tank unloaded (0 bar); it is recommended to

depressurize the tank again, in case the compressor has stopped at

low temperature within 30 minutes from the first start up.

COMPRESSORS WITH λD STARTING

CONTROL UNIT (fig. 16)

Fit the plug in the power socket (fig. 13) and turn the pressure switch

to position “I” (ON) (fig. 17). Turn the master power switch “A” on the

control unit to position "I" – power On is signalled by white indicator-

light “E” going on. Turn switch “B” to position 1 to start the compressor.

If the solenoid-valve indicator-light “D” and the motor indicator-light

"C" go on in that order, this means the machine is operating perfectly

(fig. 18).

COMPRESSORS WITH TIMED

CONTROL UNIT (fig. 17)

Fit the plug in the power socket (fig. 13) and turn the pressure switch

to position “I” (ON). Turn the master power switch “A” on the

control unit to position 1 – power On is signalled by white indicator-

light “E” going on; turn switch “B” to start the compressor.

Pos. 1 pumping element n. 1 only is operating; Pos. 2 pumping

element n. 2 only is operating; Pos. 3 both pumping elements are

operating simultaneously, at staggered starting times.

The compressor is fully automatic, and is controlled by the pressure

switch which stops it when tank pressure reaches maximum value

and restarts it when it falls to minimum value.

NOTE:

The head/cylinder/delivery tube unit can reach high

temperatures. Take care when working near these parts, and do not

touch them to avoid possible burns (fig. 18 - 19).

IMPORTANT

The electro-compressors must be connected to a power socket

protected by a suitable differential switch (thermal-breaker). If the

breaker is tripped, the compressors restarts automatically after 10

to 15 minutes. The motors of compressor models TWINMAX 420 /

TWINSTAR 470 are supplied with a manually resetting automatic

amperometric thermal-breaker, located outside the terminal board

cover. When the breaker is tripped, wait for a few minutes and then

reset the breaker manually (fig. 20). The motors of the compressors

are supplied with a manually resetting amperometric thermal-breaker,

located on the terminal board cover. When the breaker is tripped, wait

for a few minutes and then reset the breaker manually (fig. 20).

The safety device is automatic in three-phase and Silent compressors.

When the thermal-breaker is tripped, the pressure switch is released

to “0” (OFF) position. Wait for a few minutes and return the pressure

switch to “I” (ON) position. For compressors supplied with a control

unit, the thermal-breaker is installed inside the control unit.

When the thermal-breaker is tripped, observe the following procedure

(fig. 22):

-

Turn the switches on the control unit cover to position “0”,

open the cover and press push-button 1 of the thermal-breaker.

Close the cover of the control unit and restart the compressor,

observing the operations described in the paragraph “Starting

compressors with control unit”.

The same instructions apply to compressors powered at 60 Hz.

ADJUSTING OPERATING PRESSURE (fig. 23)

You do not have to use the maximum operating pressure at all

times. On the contrary, the pneumatic tool being used often requires

less pressure. On compressors supplied with a pressure reducer,

operating pressure must be correctly adjusted. Release the pressure

reducer knob by pulling it up, adjust pressure to the required value by

turning the knob clockwise to increase pressure and anti-clockwise to

reduce it. When you have obtained optimum pressure, lock the knob

by pressing it downward (fig. 23). For pressure reducers equipped

without a pressure gauge, the set pressure can be seen on the

graduated scale located on the reducer body. On pressure reducers

equipped with a pressure gauge, pressure can be seen on the gauge

itself. WARNING: Some pressure regulators do not have “push to

lock”, therefore simply turn the knob to adjust the pressure.

MAINTENANCE

Before attempting any maintenance jobs on the compressor, make

sure of the following:

– Master power switch in position “0”.

– Pressure switch and the control unit switches all off, in position “0”.

– No pressure in the air tank.

Every 50 hours of duty: we advise you to dismantle the suction filter

and clean the filtering element by blowing compressed air on it (fig.

24). You are recommended to replace the filter element at least

once if the compressor operates in a clean environment, but more

frequently if in a dusty environment. The compressor generates

condensate water which accumulates in the tank. The condensate

in the tank must be drained at least once a week, by opening the

Содержание MOUNMOUNTAINE 1450

Страница 3: ...3...

Страница 4: ...4...

Страница 5: ...5...

Страница 67: ...1127340062 10 2018 EU...

Страница 68: ......