- B1 -

0700_ GB-Gelenkwelle_BA-ALLG

GB

DRIVESHAFT

Supplement - B

Rules for working

Never exceed the maximum p. t. o. speed when using

the implement.

- When the p.t.o. is switched off, the implement hitched

up may not stop at once.

Do not go close to the implement until all motion has

stopped; only then may work be done on it.

- When the implement ist parked, either remove the

driveshaft and store it, or secure it with a chain. Do

not use retaining chain (H) for this.

Wide-angle joint:

Maximum angle of deflection when working/stationary:

70°

Standard joint :

Maximum angle of deflection when stationary: 90°

Maximum angle of deflection when working: 35°

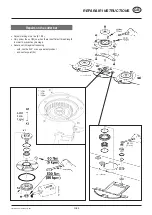

Maintenance

Replace worn-out covers/guards at

once.

- Lubricate with a brand-name grease before starting

work and every 8 hours worked.

- Before any extended period of non-use, clean and

lubricate driveshaft.

For

winter working, grease the tube guards, to avoid

them freezing together.

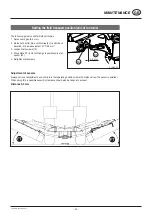

Matching driveshaft to tractor

To determine the actual length required, hold the two

halves of the driveshaft side by side.

Procedure for cutting to length

- To determine length required, set implement in closest

working position (L2) to tractor, hold driveshaft halves

side by side and mark off.

Important!

• Note the maximum operating length (L1)

- Try to attain the greatest possible shaft over-

lap (min.

1

/

2

X)!

• Shorten inside and outside tube guard by the same

amount.

• Fit torque limiter (2) of drive shaft to implement end of

driveshaft!

• Always check that drive shaft locks are securely

engaged before starting work.

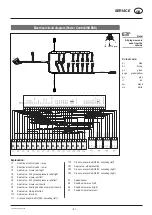

Retaining chain

- Use chain to prevent tube guard from rotating.

Take care that chain does not impede driveshaft

pivoting.

8

h

FETT

Important!

Only use the indi-

cated or accom-

panying drive

shaft, otherwise

the right to claim

under guarantee

for any possible

damage does not

exist.