Maintenance

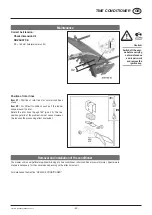

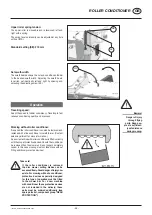

Cleaning: (every 20 operating hours)

• Unscrew the covers and maintenance openings (WA)

during belt and chain drive

• Remove deposited dirt

• Clean rubber rollers

Dirt can impair lubrication that will

subsequently cause equipment damage!

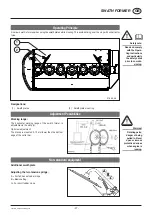

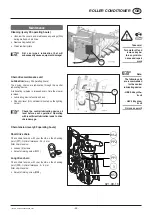

Chain drive maintenance unit

Lubrication:

(every 20 operating hours)

The driving chains are lubricated through the central

lubricating device.

A lubricating impulse is released every time the mower

is raised

• Lubricating device function check

• Check oil level. (Oil container is located on the lighting

carrier)

Check the central lubricating device oil

level before each operation. Operating

with insufficient lubrication leads to drive

chain damage.

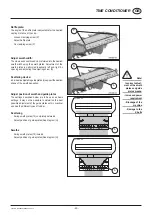

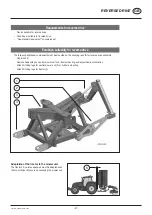

Chain tension: (every 60 operating hours)

Short drive chain

Check chain tension with your thumb on the checking

point (PP1). Optimal tolerance: 3.5 –5 mm.

Alter chain tension:

• Loosen (3) screws

• Adjust straining screw (WS1)

Long drive chain

Check chain tension with your thumb on the checking

point (PP2). Optimal tolerance: 5 – 8 mm.

Alter chain tension:

• Adjust straining screw (WS2)

WS1

3

PP1

PP2

WS2

021-09-16

021-09-20

Take care!

Turn motor off and

remove key be-

fore any mainte-

nance and repair

work

WA

S

Note:

The following oils

are recommended

for the central

lubricating device:

- HEES 46 synthe-

tic oil

- HLP 46 hydrau-

lic oil

Only use new oil!

- 45 -

1000-GB_WALZENAUFBEREITER_3843

ROLLER CONDITIONER

GB