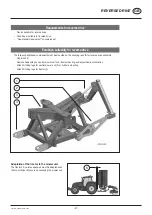

Take care!

Turn motor off

and remove key

before any main-

tenance or repair

work!

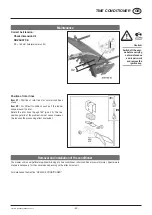

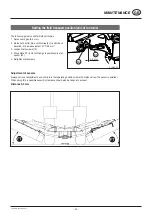

• Set belt tension by turning the perforated disk (L)

• Set the roller position by moving the tensioning block

(S)

- Set the roller so that the belt runs centrically

Possible causes for high belt wearing:

- Belt tension to tight

- Belt not running centrically

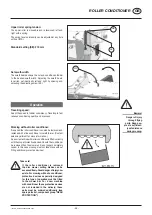

Setting belt tension:

• Pretension belt at approx. 0.4 – 0.5 %

Setting

advice:

- Mark loose belt at 2000mm (see sketch)

- Tension belt until marked distance reaches 2008

– 2010 mm0

Setting feed-in plate:

Always set the distance between feed plate and conveyor

belt with screws (1) so that gap on conveyor belt ejector

side (A) is greater than gap on feed-in side (E).

Min.

distance: 5mm

Note:

A correctly set feed-in plate prevents

blockages and/or minimizes cleaning.

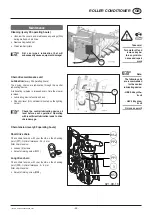

Sensor setting:

The cross conveyor belt sensor advises the swinging

status of the belt. Set the sensor distance (S) between

3 -> 5 mm.

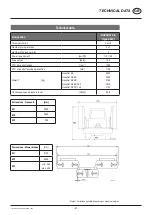

Oil change:

Interval:

Every 2 years (max. 4000 ha)

Amount:

26 litres

Type:

SAE 10W-30

Cross conveyor belt maintenance

Important!

• Check belt run af-

ter 5, 10, 20 hours

and then every 20

hours thereafter.

• The belt must not

run to the side.

•

The belt must

run centrically on

both rollers.

278-09-07

1

E

A

278-09-44

S

- 56 -

0900-GB_QUERFÖRDERBAND_3843

CROSS CONVEYOR BELT

GB

&+(

bb

¥'%

TD93/99/21

OIL

LEVEL