- 49 -

0900-GB_AUFBEREITER WECHSELN_3843

GB

REPLACE CONDITIONER

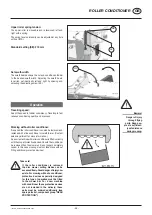

5. Open retaining bolt

The conditioners are each attached to the mower unit

with 2 retaining bolts.

Standard (A): Screw + sleeve

Non-standard equipment (B): Spring-assisted quick

closure.

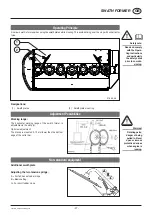

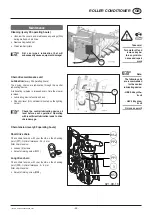

6. Disconnect lubricating line:

(The lubricating line is only attached when using

the roller conditioner!)

Close shut-off valve of central oil lubrication on coupling

jack (pos. A)

For connecting and disconnecting, push out the

connection of the lubricating line on the mower unit.

7. Remove conditioner

Install conditioner

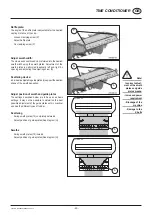

1. Clean

Clean the conditioner/swath former and the mower unit thoroughly especially the connecting points.

2. Push conditioner or swath former into mounting of mower unit.

3. Close retaining bolt

Standard (A): Screw + sleeve

Standard equipment (B): Spring-assisted quick closure.

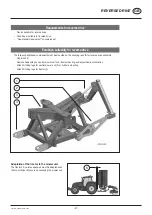

4. Disconnect chassis

5. Adjust and secure conditioner fixing

The optimum alignment between mower unit and conditioner is adjusted using the conditioner fixing (1). The belt pulleys

on the inside of the conditioner must be aligned flush with the belt pulleys of the mower unit. Secure conditioner

fixing!

6. Install belt, tension and attach protective cover.

For details see the Section “Dismantle conditioner”

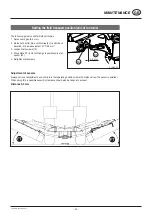

7. Connect lubricating line (only with roller conditioner)

Open shut-off valve of central oil lubrication on coupling jack (pos. E)

8. Adapt relief pressure to mower unit:

The relief pressure of the mower unit must be reset after installation of the new conditioner.

The following are deemed to be guide values for the “hydraulic pressure relief” version:

Swath former:

90 - 100 bar

Tine

conditioner:

130 - 140 bar

Roller conditioner:

160 - 170 bar

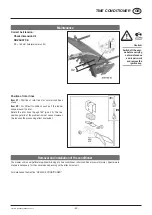

9. Adjust lighting beam

The lighting beam can be changed in length depending

on the conditioner or swath former using an adaptor

(Z).

A

B

Tip!

Checking the

correctly adjusted

relief pressure:

The mower unit

can be raised

manually on the

outside (approx.

80 kg).

1

278-09-70

Z