9/24

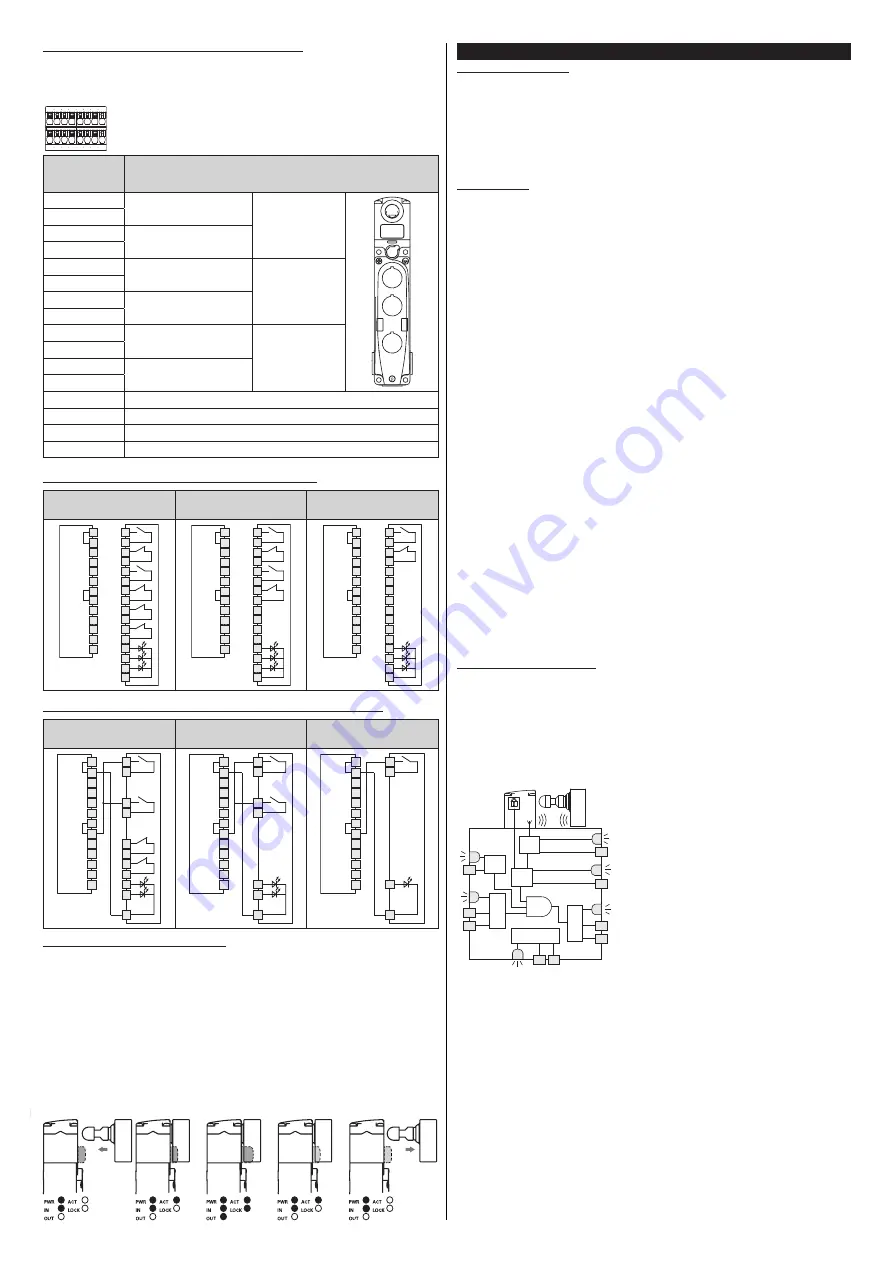

4.10.2 Internal connections of integrated control devices

The switch can be supplied with a cover equipped with between one and three

integrated control devices. The below illustrates the standard connections for these

devices. Other configurations are available on request.

27

28 29 30 31 32 33 34

19

20 21 22 23 24 25 26

Internal terminal

strip integrated

control devices

Connection

19

Contact 1

Device 1

1

2

3

20

21

Contact 2

22

23

Contact 1

Device 2

24

25

Contact 2

26

27

Contact 1

Device 3

28

29

Contact 2

30

31

Supply input +24 Vdc / LED device 1

32

Supply input +24 Vdc / LED device 2

33

Supply input +24 Vdc / LED device 3

34

Supply input 0 V / LED

4.10.3 Switch with integrated field-wireable control devices

NG 2D

••••

1C

NG 2D

••••

1D

NG 2D

••••

1E

NG 2D

••••

1F

NG 2D

••••

1G

NG 2D

••••

1H

15

16

1

2

3

4

5

6

10

11

12

13

14

B2

I4

O3

O4

I3

A1

B1

IS1

IS2

OS1

OS2

A2

I5

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

15

16

1

2

3

4

5

6

10

11

12

13

14

B2

I4

O3

O4

I3

A1

B1

IS1

IS2

OS1

OS2

A2

I5

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

15

16

1

2

3

4

5

6

10

11

12

13

14

B2

I4

O3

O4

I3

A1

B1

IS1

IS2

OS1

OS2

A2

I5

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

4.10.4 Switch with integrated control devices and M23 connector, 19-pole

NG 2D

••••

1C-K603

NG 2D

••••

1D-K603

NG 2D

••••

1E-K602

NG 2D

••••

1F-K602

NG 2D

••••

1G-K601

NG 2D

••••

1H-K601

B2

I4

O3

O4

I3

A1

B1

IS1

IS2

OS1

OS2

A2

I5

4

5

19

19

1

8

9

7

6

6

2

3

12

6

6

19

17

14

15

13

11

10

18

16

1

B2

I4

O3

O4

I3

A1

B1

IS1

IS2

OS1

OS2

A2

I5

4

5

19

19

1

8

9

7

6

6

2

3

12

6

6

19

17

15

18

16

4

5

19

19

1

8

9

7

6

6

2

3

12

B2

I4

O3

O4

I3

A1

B1

IS1

IS2

OS1

OS2

A2

I5

6

17

19

18

4.11 RFID sensor intervention points

The RFID sensor on the device recognises the actuator when placed in front of it.

Within this range the signalling output O3 is activated along with the ACT LED to

indicate the “guard closed” condition. In this condition, it is possible to lock the “guard

closed” state by means of the I4 input. After locking, the LOCK LED and the output

O4 are activated. At the same time the RFID sensor extends its release distance to

prevent vibrations or impacts from causing involuntary opening of outputs OS1, OS2

and O4 when the guard is locked. If the input I4 (or IE1/IE2) is activated or deactivated,

without the actuator present, the device does not lock or activate any of the outputs

OS1, OS2, O4. To open the guard it is necessary to operate via the input I4; with guard

unlocked, output O4 will be deactivated and the LOCK LED will switch off. At this point,

the RFID sensor will reset its operating distance to the initial values and by opening

the guard the output O3 and the ACT LED will be deactivated.

5 OPERATION

5.1 Access monitoring

These devices alone are not sufficient to protect any operators or maintenance

engineers in the event that they are able to physically enter the danger area with their

whole body, since any unintentional closing of a guard behind them could allow the

machine to be restarted. In case the machine restarting control is entirely entrusted

to these switches, a device must be provided to avoid that risk, such as a lock-out/

tag-out system which stops the machine from being restarted. A specifically designed

lock-out/tag-out device is available as an accessory for the switch, which prevents any

unintentional machine start up with the operator still inside. Please contact our sales

offices for more information (see paragraph SUPPORT).

5.2 Definitions

States of the switch:

• OFF: device is off, not powered.

• POWER ON: state immediately following switch on, during which the device carries

out internal tests.

• RUN: state in which the device is working in normal operation.

• ERROR: error state in which the safety outputs are disabled. Indicates presence of a

failure, either internal or external to the device, such as for example:

- a short circuit between the safety outputs (OS1, OS2),

- a short circuit between a safety output and the ground,

- a short circuit between a safety output and the supply voltage,

- an excessive misalignment between the switch and the locked actuator,

- an exceedance of the maximum retention force with failure of the device in locked

condition,

- an exceedance of the maximum or minimum admissible ambient temperature,

- an internal failure.

• The safety functions are defined as follows.

Mode 1:

1.1 The OS safety outputs must be disabled when the actuator is

detected as released.

1.2 The OS safety outputs must be disabled when the actuator is no

longer detected.

1.3 The OS safety outputs must be disabled when at least one of the

safety inputs (IS1 or IS2) is not enabled.

Mode 2:

2.1 The OS safety outputs must be disabled when the actuator is no

longer detected.

2.2 The OS safety outputs must be disabled when at least one of the

safety inputs (IS1 or IS2) is not enabled.

Mode 3:

3.1 The OS1 safety output must be disabled when the actuator is

detected as released.

3.2 The OS2 safety output must be disabled when the actuator is no

longer detected.

3.3 The OS1 safety output must be disabled when the IS1 safety input

is not enabled.

3.4 The OS2 safety output must be deactivated when the IS2 safety

input is not enabled.

With any operation mode the device must keep the guard closed and locked when

the solenoid is enabled (working principle E for versions NG 2D1E••••, NG 2D7E••••)

or disabled (working principle D for versions NG 2D1D••••, NG 2D5D••••, NG

2D6D••••, NG 2D7D••••) and a force less than the declared value F

Zh

is applied.

• The EDM External Device Monitoring function (where present) is a function which

allows the device to monitor the state of external contactors. Activation and deac-

tivation of external contactors must follow the NG switch safety outputs within a

maximum delay.

5.3 Description of operation

Note: the following functional descriptions refer to a device with safety outputs enabled

with guard closed and locked (mode 1).

A device with safety outputs enabled by closing the guard (mode 2) dif-

fers from the above operating mode for the fact that the safety outputs OS1

and OS2 are enabled without the f4 function verifying the guard locking.

Mode 3 differs, in that OS1 is enabled when the guard is closed and locked, and OS2

with guard closed.

Following correct installation in accordance with these instructions, the safety device

can be powered. The diagram below represents the 5 logic functions which interact

inside the safety device.

f4

f1

f2

f3

f0

OS1

OS2

IS2

IS1

IN

O4

PWR

A2

A1

O3

OUT

CODE

ACT

LOCK

I5

EDM

f5

In the initial "POWER ON" state, the safety device

f0 function carries out an internal self diagnosis.

When this terminates successfully, the device

switches to the "RUN" state. If the test is not

passed because of an internal failure, the device

enters the "ERROR" state.

In EDM versions, on power-up, the EDM signal is

checked and must be active within 500 ms from

device start. If the EDM signal is not present, after

the delay time the F5 function sets the device to

the FAULT state.

The "RUN" state is the normal operation state: the

f1 function evaluates the state of inputs IS1, IS2;

at the same time the f2 function checks the pres-

ence of the actuator and the f4 function verifies

that the actuator has been locked.

In the EDM versions the f5 function verifies the

coherence of the EDM signal during state chang-

es and when the safety outputs are off.

When these three conditions are given, the f3 function of the device enables the safety

outputs OS1 and OS2.

The device inputs IS1 and IS2 are normally activated simultaneously and so are

monitored both for state and coherence. In the event of deactivation of just one of

the two inputs, the device deactivates the safety outputs and signals a non-coherent

condition of the inputs via the IN LED flashing green/orange. In order to reactivate

the safety outputs, both inputs have to be deactivated and subsequently reactivated.

In the RUN state, function f0 carries out internal test cycles in order to identify any

failures. Detection of any internal error switches the device to the "ERROR" state

(PWR LED continuously red) which deactivates immediately the safety outputs.

The "ERROR" state can be reached also where short-circuits between the safety

outputs (OS1, OS2), or a short circuit of an output towards ground or towards the

supply voltage, are identified. In this case also, the F3 function deactivates the safety

outputs and the error state is indicated by the OUT LED flashing red.

The O3 signalling output activates during the "RUN" state, at the actuator insertion

into the device, independently of the state of the IS1 and IS2 inputs. The state of this

output is displayed via the ACT LED.

The O4 signalling output activates during the "RUN" state, when the actuator has

been introduced and locked into the device, independently of the state of the IS1 and

IS2 inputs. The state of this output is displayed via the LOCK LED.

The actuator lock or release command is transmitted to the device through the I4

input.